| Diode Pumped Solid State Laser Laboratory |

High energy lamp-pumped Q-switched Nd:YAG laser for laser shock peening studies:

Unstable resonator configurations with variable reflectivity mirror (VRM) having super Gaussian reflectivity profile has been widely used for generating higher output energy in a smooth spatial profile offering all benefits both in near and far field applications. Using 10mm diameter Nd:YAG rod in positive branch unstable resonator we have developed a high energy 1.2 J flash lamp pumped Electro-optically (E-O) Q-switched Nd:YAG laser system for laser shock peening studies. The measured output pulsewidth and beam propagation factor (M2) are 7 ns and 3.5, respectively.

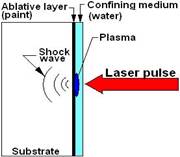

Laser shock peening is an upcoming non-contact surface treatment process for inducing high level of surface compressive stresses, without adversely affecting surface finish of the substrate. The process has large untapped potential in enhancing life of engineering components operating under fatigue and stress corrosion testing. It involves irradiation of painted surface of substrate by high-energy nanosecond laser pluses, while maintaining a layer of flowing water on the surface. Instantaneous formation of high-pressure plasma causes

a shock wave to travel into the material thereby generating compressive residual stresses on the surface of the substrate. Initial experiments revealed that laser shock peened surface developed about 450 m thick compressed layer with surface stress lying in the range of -375 to -550 MPa on 5 mm thick SAE 9260 spring steel.

|

|