- Development of high beam quality Copper Vapour Lasers (CVLs)

The different variants of Copper Vapour Lasers (CVLs), Copper Bromide Lasers and Copper HyBrID Lasers with single unit of average laser power varying from 20 W to 100 W are developed. These lasers operate with pulse repetition rates of (5 to 20 kHz) and pulse width of typically 40 ns. The laser wavelengths of these units are at 510 nm (green) and 578 nm (yellow). The diffraction limited beams are available with the use of novel resonator schemes.

- Nonlinear UV frequency conversion of CVL

Fibre Grating Lab (FGL) of FSOSS is involved in R & D of generation of coherent high power UV radiations at multiple wavelengths of 255 nm, 271 nm and 289 nm. This is achieved by non-linear frequency conversion of CVL radiations at 510 nm and 578 nm in beta-BBO crystal. Average UV power of the order of 1 W for all UV wavelengths has been achieved. About 2.0 W UV power at 255 nm was generated from single oscillator and amplifier system using pump power of 11 W.

- Development of fibre grating fabrication facility

(i) Fibre Bragg grating (FBG) inscription setup

The UV radiations generated from second harmonic/sum frequency (255 nm, 271 nm and 289 nm) of Copper Vapour Laser (CVL) is an attractive choice for high-speed fabrication of FBGs because of its high repetition rate, low peak power, high temporal and spatial coherence. FBG is made by inducing refractive index modulation by spatially patterned UV radiation in the core of a doped photosensitive optical fibre. The FBG fabrication facility based on phase mask and interferometric techniques has been developed. Typical parameters of FBGs that can be inscribed on the facility are as follows.

Wavelength range : 1525 nm to 1560 nm

Gauge length : 3 mm to 15 mm

Reflectivity : > 90 %

Bandwidth (at FWHM) : 0.3 nm to 0.7 nm

Fibre type : Photosensitive single mode optical fibre

Temperature range : 20 to 900 oC

Types of gratings : uniform, regenerated and chirped

FBGs in optical fibre : Single/Multiple

(ii) Long period fibre grating (LPFG) inscription setup

LPFG inscription set up based on point-by-point (PBP) method has been developed in Fibre Grating Lab (FGL), FSOSS, RRCAT exploiting the photosensitivity of germane-silicate fibre to 255 nm UV radiations. This is in sequel to the fabrication of FBGs by 255 nm UV beam in this centre. The permanent change in refractive index upon UV illumination is associated with the formation of Ge-related glass defects.

- Development of fibre optic sensors

(i) FBG based single point temperature sensors

Several FBG sensors are developed for temperature sensing applications. A setup has also been developed to calibrate the in-house fabricated FBG sensors against a standard temperature sensor. FBG sensors have typical sensitivity of 11.6 pm/°C. The resolution and accuracy of temperature measurement using FBG temperature sensors was ~1°C. The maximum operating temperature of FBG sensors were ~ 400 °C, ~ 700 °C and ~ 1000 °C with Type I, Type IIa and regenerated FBG respectively.

(ii) FBG based quasi distributed temperature sensors

The FBGs at multiple wavelengths, in a single fibre, are made by either tilting the phase mask or the fibre with respect to each other, by splicing the individual FBGs inscribed at different wavelength using phase mask of different period and by using single bi-prism with diverging/converging UV beam.

(iii) FBG based strain sensors

FSOSS, RRCAT has developed FBG based single point strain sensor. For a typical germanosilicate optical fibre p11 = 0.113, p12 = 0.252, ν = 0.16 and neff =1.482. This gives a strain-optic constant of 0.22 for germanosilicate fibre. The typical strain sensitivity was about 1.02 pm/με.

(iv) FBG based refractive index sensor

A hydrogen fluoride (HF) etched FBGs based refractive index sensor has been developed in Fibre Grating Lab. (FGL), FSOSS, RRCAT. The clad of the fibre around FBG is partially removed by HF etching to make it sensitive to changes in the surrounding medium refractive index. This etched FBG was used for refractive index sensing.

(v) Raman optical fibre distributed temperature sensor (ROFDTS)

In a Raman optical fibre distributed temperature sensor (ROFDTS) system, the optical fibre itself acts as an array of several sensing elements. Every bit of optical fibre plays the dual role of sensing elements and data transmitting medium. The sensing fibre can also replace numerous point sensors (like thermocouples, RTDs etc.) and wires allowing reduced complexity. In addition to fire detection in power cables, ROFDTSs have attracted the attention as a means of temperature monitoring in numerous areas like long gas pipelines, oil wells, sodium coolant loop of fast breeder test reactor, tunnel of CERN etc. The developed ROFDTS hasthe following specifications.

Temperature range : 25 – 300 °C

Sensor length : up to 200 m

Temperature accuracy : ± 4.5 °C

Temperature resolution : 3 °C

Spatial resolution : 1 m

Sampling over fibre length : every 10 cm

Measurement time : 10 s, optimized for fire detection

- Instrumentation for optical fibre sensors

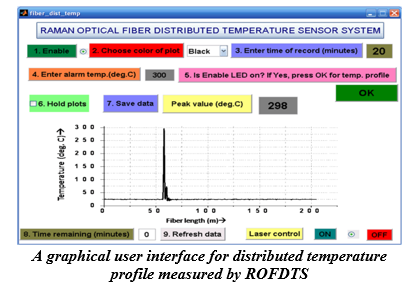

(i) Instrumentation, advanced digital signal processing modules and user interface for ROFDTS system

The development of instrumentation and signal processing modules for ROFDTS involves following design components.

- Design and development of very fast and low power Raman anti-Stokes (AS) and Stokes (St) signal electronic circuits using photomultiplier tubes.

- Design and development of dynamic auto calibration circuitry using Arduino microcontroller for ROFDTS

- Design and implementation of advanced non-stationary digital signal processing models for Raman AS and St signals using short-term Fourier transform (STFT), discrete wavelet transform (DWT) and empirical mode decomposition (EMD)

- Development of a novel parameter called ‘area’ of intrinsic mode functions (IMFs) of Raman Stokes signal for automatic detection of temperature error induced by an undesired and unnoticed bend in sensing fibre anywhere over the full length of fibre.

- Design and implementation of a user friendly graphical user interface for ROFDTS for automated operation of ROFDTS.

- Design and development of user programmable audio-visual zone indicators with acknowledge and zone reset functions in a ROFDTS based distributed fire sensor.

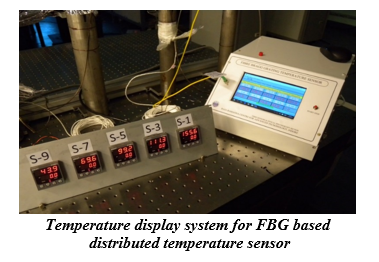

(ii) Automated temperature display system for FBG based distributed temperature sensor

A compact, portable and standalone multipoint temperature display unit has been designed and developed for display of temperature of 10 points using 10 point FBG sensor array and interrogator. The temperature demodulation algorithm for all the FBGs is implemented by the microcomputer of the unit. A user friendly graphical user interface is run on the touch screen of the display unit. The temperature of all the FBGs is made available on the screen without requiring any assistance of the operator automatically and it also takes care of the temperature calibration of every FBG. The unit can record and store the temperature profile with time and date stamp for future reference. The potential free contacts for audio-visual alarms corresponding to certain temperature threshold values can also be provided on users’ demand. The graphical user interface can also be designed in accordance with the users’ requirements.

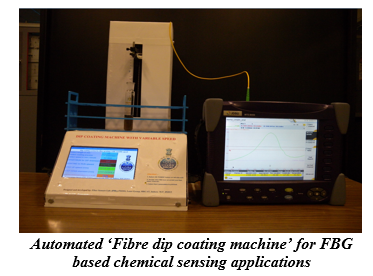

(iii) Automated ‘Fibre dip coating machine’ for FBG based chemical sensing applications

FBG based chemical sensors aim at identification/quantification of adulterations, contaminations, explosive gases, humidity etc. FBG chemical sensors involve coating of thin film of suitable material e.g. graphene oxide, poly-vinyl alcohol, metal nanoparticles etc. for enhanced sensitivity and selectivity. The thickness and uniformity of coating film decide the performance of the sensor head. Dip coating is the process of coating of desired material onto a substrate by immersing in a solution of the material to be coated and then pulling it out at a constant velocity. In the coating process, the precise pull out velocity and number of rounds govern the thickness and uniformity of the material to be coated. Hence, the dip coating process requires a precise control and high degree of repeatability. Therefore, an automated version of dip and coating process is of utmost importance. Looking at above requirement, the design and development of an engineered stand-alone version of a portable and compact ‘Fibre dip coating machine’ has been designed and developed. The whole system consists of stepper motor driven ‘Dipping module’, ‘Vessel platform’ and ‘Control & display unit’. The ‘Fibre Dip coating machine’ is equipped with various features such as selectable coating length (5-25 mm), coating/pullout speed (0.125-30 mm/minute) with precise control on coating length and coating speed. The system has been developed using Raspberry-Pi controller with user interface developed with Python. The ‘Touch screen display based user interface’ allows the user to control and select various parameters of dip and coating process.

- Deployment of fibre optic sensors for various field applications

(i) FBG based temperature monitoring system for oil immersed ferrite core pulse transformer

FBG based temperature measurement of oil immersed ferrite core pulse transformer for high voltage pulse power supply rated for 25 kV is developed and installed. The temperature is varied from 20 °C -120 °C.

(ii) Multipoint temperature monitoring of CuBr laser tube in high voltage and high EMI environment

The CuBr laser operating conditions, such as high-repetition rate and high-specific power, demand high-electrical power loading. The high electrical power loading is a source of high-electromagnetic noise both at the power supply and laser head. FBG based multipoint temperature sensor is fabricated and deployed.

(iii) FBG based distributed sensor system for temperature monitoring of dipole chamber of Indus-2

Fibre Bragg grating based 20 point distributed temperature sensor is developed at Fibre Grating Lab, FSOSS RRCAT, and deployed to monitor the temperature of vacuum chamber wall of dipole magnet (DP-02 and DP-12) in Indus-2. The temperature at specific locations can be monitored online with accuracy of ± 1 °C in the presence of high electromagnetic interference. The temperature of the dipole chamber wall (DP-12) varied from 18 to 37 °C during the operation of Indus-2.

(iv) FBG temperature sensor at storage vault of SSSF, NRB, BARC, Tarapur

A fibre Bragg grating based temperature sensor is developed and deployed for temperature monitoring of storage vault at Solid Storage and Surveillance Facility (SSSF), BARC, Tarapur in high radiation environment. The radiation level at the sensor location was ~ 7000 rad/hour. The temperature was monitored online and found to be varied from 35 oC to 45 °C. The accelerated radiation testing of FBG sensor is also carried out upto accumulated dose of 100 Mrad at High Intensity Radiation Utilization Project (HIRUP) at BARC.

(v) FBG temperature sensor for temperature measurement of microwave heated nuclear fuel processing chamber

A FBG based temperature sensor set-up is developed at Fibre Grating Lab (FGL), RRCAT and deployed at Fuel Fabrication (FF), BARC, Tarapur, to monitor the temperature of microwave heated nuclear fuel processing chamber. The sensor head consisted of thermally regenerated FBG encapsulated in the ceramic tube of diameter 5 mm and length 40 cm. The temperature data was recorded and displayed by in house developed software. The maximum temperature of the process chamber was ~ 700 °C.

(vi) Deployment of Raman optical fibre distributed temperature sensor (ROFDTS) system

(a) Temperature mapping at the surface of Dipole-2 bending magnet of Indus-2

A radiation resistant 100/120 µm Multimode sensing fibre has been laid in a spiral configuration on the ante vacuum chamber of Dipole-2 magnet of Indus-2 synchrotron storage ring. The scheme used for laying of sensing fibre on the top surface of bending magnet (length ~2.7 m, 1.5 T) is depicted in following figure.

The results of distributed temperature measurement show a non-uniform surface heating of dipole surface as the electron beam current reaches to 134 mA at 2.5GeV energy. The top surface temperature is highest (45 ᵒC) at 1.8 m location of Dipole-2 with respect to entry port of electron beam into the Dipole-2. It is observed that some portions get heated up to 22 ᵒC above ambient temperature (23 ᵒC) and may require corrective action on beam dynamics by Control Room of Indus-2. Figure presents the distributed temperature profile of the top surface of Dipole-2 bending magnet.

<

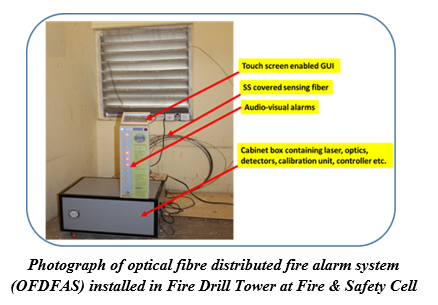

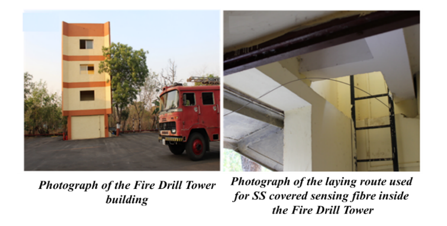

(b) Deployment of an engineered version of portable and compact optical fibre based fire detection system in ‘Fire Drill Tower’ at Fire & Safety Cell

A portable and compact optical fibre distributed fire alarm system (OFDFAS) based on ROFDTS has been developed. The optical fibre sensor (type Multimode) of length 100 m having core/clad size of 62.5/125 µm which is covered inside an SS tube of diameter 2.0 mm was coupled to the 1064 nm based diode pumped solid state laser. The distributed temperature demodulation algorithm with capability of eliminating the optical fibre induced attenuation dependent error in temperature measurement was also implemented in LabVIEW. The developed OFDFAS was installed in fire drill tower which is a 30 feet high building having two floors. Figures depict the photograph of the OFDFAS installed in the building of Fire Drill Tower and the building of Fire Drill Tower. The sensing fibre was laid in ground, first and second floors and was routed through the window of ground floor room and the gaps available between the floors as shown in the third Figure.

(vii) Deployment of FBG based wheel Impact Load Detection system sensors for Railway safety

FBGs developed at RRCAT were used for the development of wheel impact load detection (WILD) system for railway safety. This study is carried out by ‘Lab-2-Market (L2M)’ (a start-up of IISc, Bengaluru). For measuring the load on the rails, FBG strain sensor was mounted on the web in the inter-sleeper region for vertical load as shown in figure.

- Customized FBG/ROFDTS/technological support through ‘RRCAT Incubation Centre’

Following technologies developed by FSOSS, RRCAT and related technological support are available for induction in Industry.

- Customised FBG temperature sensors

- Raman optical fibre distributed temperature sensor (ROFDTS) system

- Related technological support

The above technologies can be used and owned through the Incubation Centre at RRCAT (IC-RRCAT) which has been established to provide a suitable platform to the business incubates, startups and other Industries having interest in above technology areas.

More details about Incubation Centre at RRCAT (IC-RRCAT) are available at following link

https://www.rrcat.gov.in/organization/cat/incubation/index.html

- CVL pumped dye lasers

Tunable visible radiation sources (550 nm - 650 nm) have been developed using CVL pumped dye laser. The dye oscillator consisted of grazing incidence grating (GIG) cavity with and without intra-cavity etalon. Average bandwidth in the range of 1500-5000 MHz was achieved from GIG cavity without intra-cavity etalon. Using intra-cavity etalon, the single axial mode operation of dye laser (line-width ~250 MHz) was achieved.The narrow band dye oscillator beam was further amplified in dye amplifier pumped by CVL MOPA beam. Average dye laser output power after first amplifier and second amplifier were 1.2 W and 3.0 W respectively. By simultaneously tuning dye laser wavelength and the phase matching angle of crystal, about 125 mW UV radiation tunable from 288 nm to 300 nm has been generated at dye laser pump power of 1.2 W.

- Isotope selective spectroscopy with high repetition rate lasers

Isotopes of the elements find important applications in medical and nuclear industries. Laser based isotopic-selective photoionization is a well proven process for separation/enrichment of the desired isotope. Lithium (Li) has two stable isotopes, namely 6Li and 7Li with the natural abundances of about 7.5% and 92.5%, respectively. Both the Li isotopes are important for nuclear industry. The Li isotopes can be used in fusion and fission reactors to generate the vast amount of clean electric power. Hence, study of separation of both the 6Li and 7Li isotopes is important. For lithium isotope separation, a facility is developed which includes the tunable lasers, hollow cathode lamps, thermionic diode ion-detector and the time-of-flight mass-spectrometer. A photograph of the developed facility is shown below.

Fibre Sensors & Optical Spectroscopy Section

Fibre Sensors & Optical Spectroscopy Section