|

A. Pulse Power Supply for High Power Laser

1. High Peak current pulsed power supply for solid state lasers

2. High voltage and high speed trigger circuits

3. 150 kJ single-shot pulsed power supplies for Nd:Glass Disk Laser Amplifiers

4. Simmer mode pulsed power supply for small-size krypton lamps

5. Development of High Power Pulse Power Supply for Copper Vapour Laser and its Application

a) Development of copper vapour laser and its variants

b) Development of pulsed power supply for copper vapour lasers

c) Application of copper vapor laser (Micromachining setup)

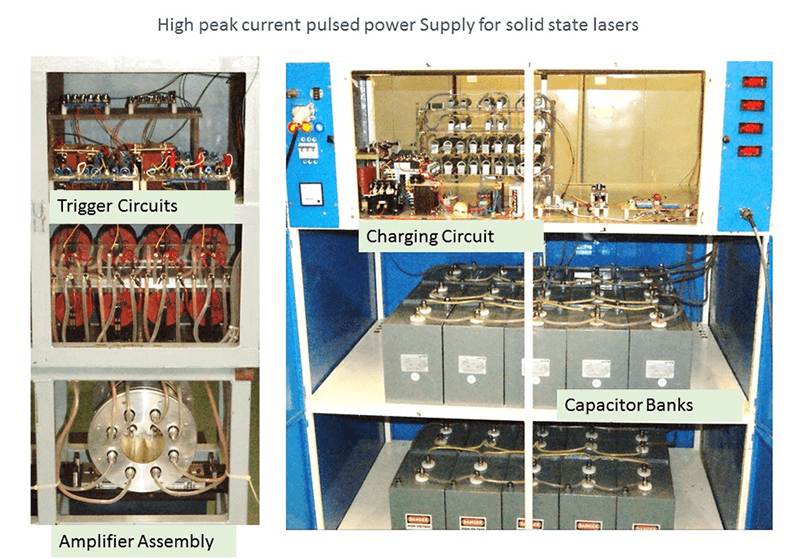

1. High Peak current pulsed power supply for solid state lasers

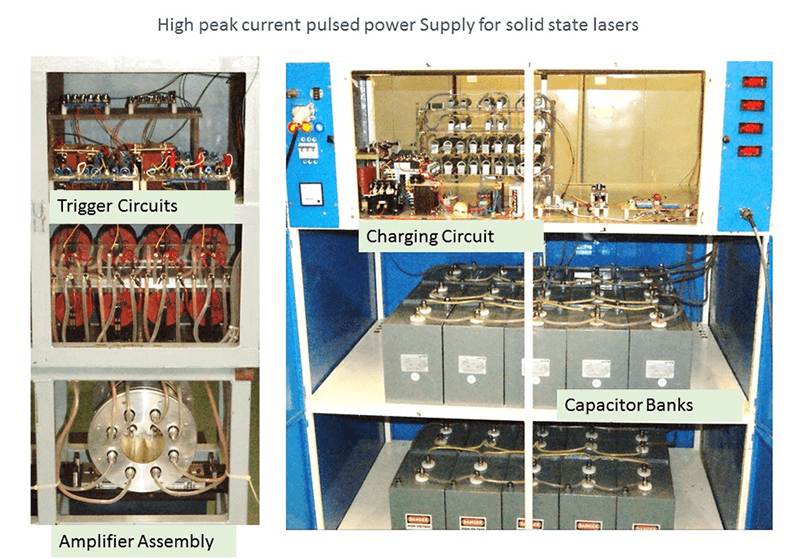

High peak current pulsed power Supply for solid state laser

The pulsed power supplies for solid state lasers consists of resonant charging circuits for large capacitor banks, Pulse forming networks (PFN), high voltage trigger circuits, interlocks and monitoring circuits. A large scale system is developed for high power high energy (400 J) 2-beam Nd: Glass laser. The stored electrical energy is of the order of (1.5 MJ) capacity. The stored energy is coupled to around 300 flash lamps of different sizes in controlled manner.

Constant current power supplies (CCPS) are developed using 50Hz resonant charging and 25 kHz resonant immittance converter topologies for capacitor banks charging. Bipolar power supplies for capacitor bank charging is design and developed for flash lamp pumped solid state lasers. High accuracy (0.1%) charging power supply is designed and developed for regenerative amplifier in OPCPA project.

Specifications of 2-beam high power laser power supply:

| S. No.

| Parameters

| values

|

| 1.

| Input

| 400 V, 3-phase, 50Hz

|

| 2.

| Charging voltage (Max.)

| 5kV

|

| 3.

| Total installed capacity

| 1.5MJ

|

| 4.

| Peak discharge current per flash

| 6kA

|

| 5.

| Charging time (Max.)

| 40s

|

| 6.

| Pulse duration

| 500us

|

| 7.

| Peak power per flash

| 2.5kJ at 500us

|

| 8.

| Repetition rate

| Single shot

|

| 9.

| Cooling mechanism

| Air cooled

|

| 10.

| Operation mode

| Unipolar/bipolar

|

Specifications of power supplies for faraday isolator:

| S. No.

| Parameters

| values

|

| 1.

| Charging voltage (Max.)

| 5kV

|

| 2.

| Installed capacity

| 16kJ

|

| 3.

| Pulse width

| 3ms

|

| 4.

| Coil inductance

| 2.5mH

|

| 5.

| Peak magnetic field

| 1.5T

|

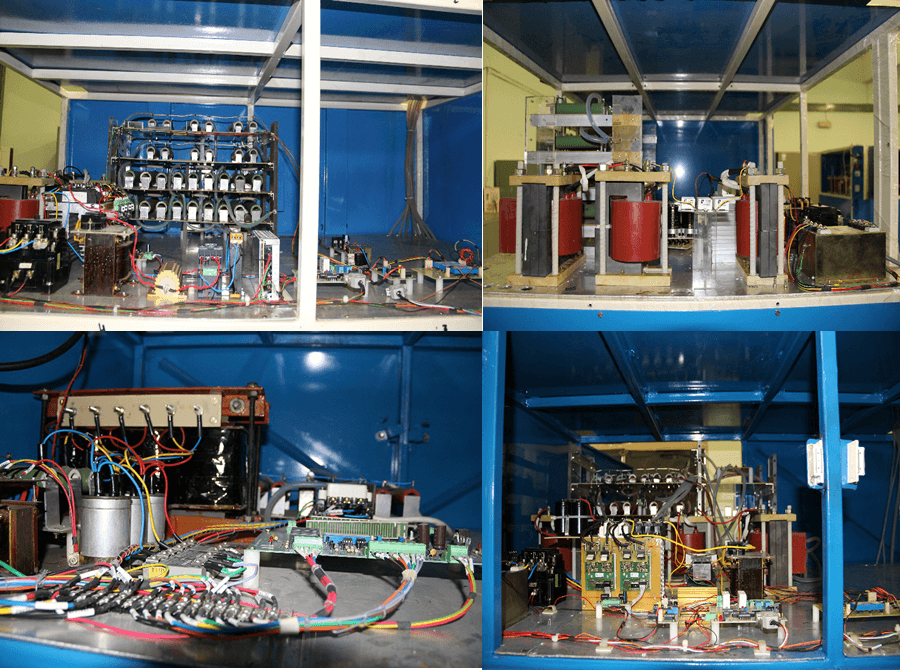

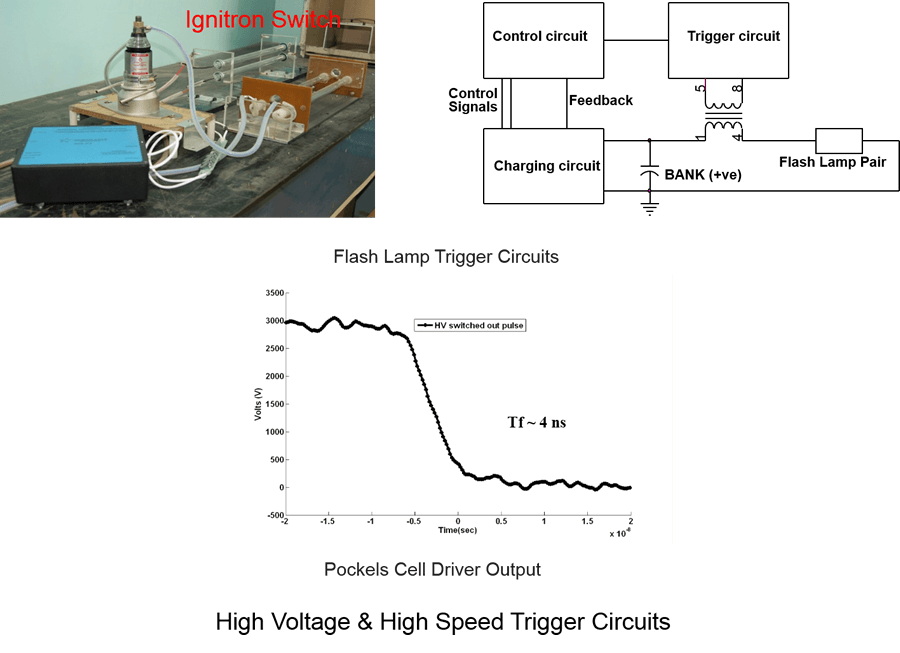

2. High voltage and high speed trigger circuits:

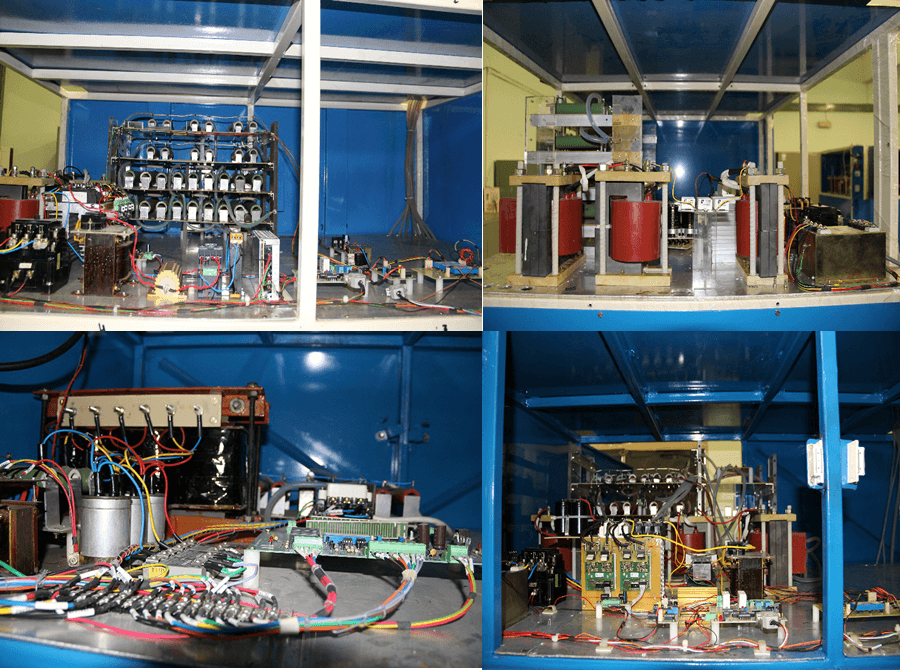

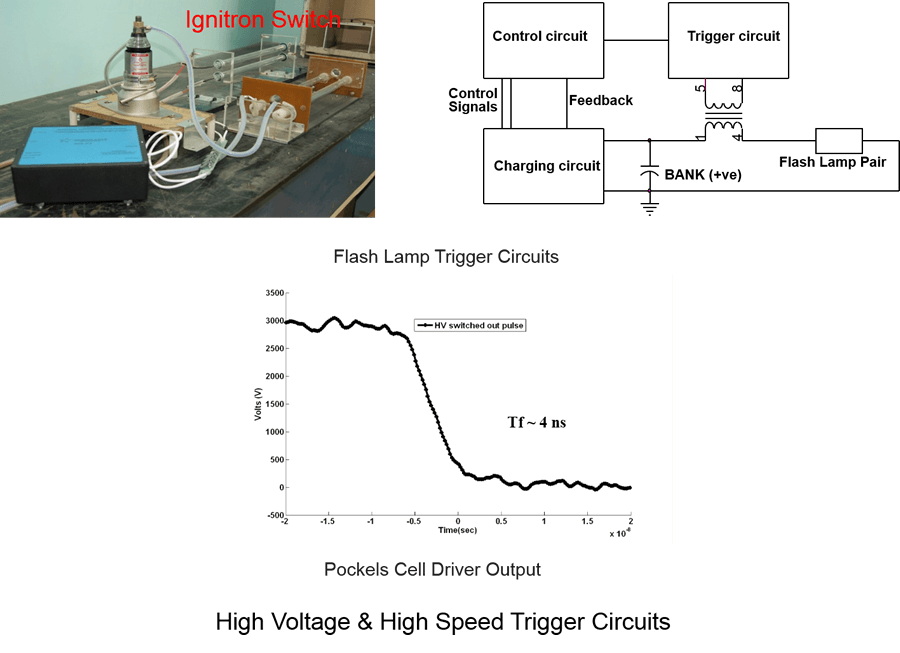

High Voltage & High Speed Trigger Circuits

High power and high energy lasers, their subsystems, laser plasma interaction experimental setups and Electro-optical devices need high voltage and fast rise time trigger signals. The division has expertise in development of trigger switches based on a variety of switches such as Ignitron, Thyratron, Avalanche transistors and SCRs for these applications.

3. 150 kJ single-shot pulsed power supplies for Nd:Glass Disk Laser Amplifiers

The pulsed power supplies consists of multiple 10 kV rated capacitor banks to store up to 150 kJ electrical energy for driving 400 mm arclength xenon flashlamps in high power pulsed mode. These flashlamps function as pump sources in Nd: glass disk based solid state laser amplifiers. Preionization scheme has been adopted to increase pumping efficiency and flashlamp life. It involves delivering a low energy prepulse prior to main discharge pulse. Prepulse is maintained within 5 to 10% of main pulse with delay of 200 μs to 300 μs between the two. A 10 kV constant current source based on resonant converter topology has been developed to charge capacitor banks. For discharge of stored energy, HV flashlamp trigger circuits based on series triggering method and high peak pulsed current (~100 kA) rated ignitron switches are used. Figure 1 shows the developed power supplies and figure 2 shows a typical flashlamp pulse.

4. Simmer mode pulsed power supply for small-size krypton lamps

Small-size krypton lamps are mostly used as pump sources in Nd:YLF or Nd: YAG based laser oscillators in high power laser chains. Simmer mode power supply have been developed to drive krypton lamps (up to 2 in series) of arc length up to 100 mm at pulse repetition rate of ≤ 10 Hz.

For better pulse-to-pulse stability and enhancement of flashlamp life, simmer mode has been incorporated wherein flashlamps are kept in conducting state by a dc current of more than 100 mA during successive pulses by a separate HV dc power supply. The flashlamps have been operated at per pulse energy of up to 240 joules at capacitor bank voltage of 2 kV. Figure 3 shows the developed power supply and figure 4 shows a typical flashlamp current pulse.

5. Development of High Power Pulse Power Supply for Copper Vapour Laser and its Application

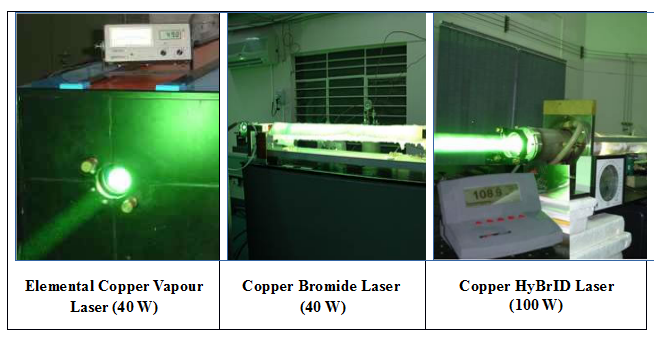

a) Development of copper vapour laser and its variants

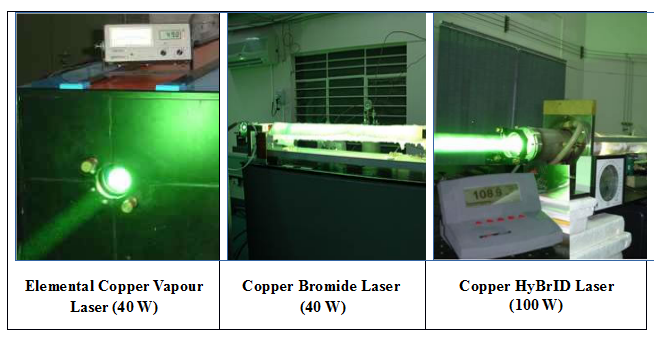

Copper Vapour Laser Electronics Laboratory works on design, development and maintenance of copper laser systems. Many models of elemental Copper Vapour Laser, Copper Bromide Lasers and Copper HyBrID lasers giving average laser power from 4 W to 100 W from single unit are developed. The lasers operate with pulse repetition rate of 5 to 20 kHz and typical pulse width (FWHM) of 40 nS. The laser wavelength of these units are 510 nm (green) and 578 nm (yellow). These lasers are used in various applications like second harmonic generation for Fibre Bragg Grating (FBG) inscription, pumping dye lasers, spectroscopy, micromachining etc.

Elemental copper vapour lasers are typically operated at 6 kHz with electrical to optical efficiency of about 1% whereas Copper Bromide and Copper HyBrID lasers operate at high repetition rate of 18 KHz with higher efficiency of 2 %. The warm time of Copper Bromide and Copper HyBrID laser is 15 min whereas elemental copper vapour laser is 45 min. The development of laser system requires multidisciplinary expertise in the field of high vacuum, high temperature, thermal insulation, high voltage, precise gas flow, precise electronic control and instrumentation and EMC/EMI.

b) Development of pulsed power supply for copper vapour lasers:

b) Development of pulsed power supply for copper vapour lasers:

The conventional design of the power supply for CVL is based on hydrogen thyratron as a high voltage, high power and high repetition rate switch in the pulse generator circuit. Modern (solid state) power supplies for the lasers are based on insulated gate bipolar transistor (IGBT) and magnetic pulse compressors (MPC). Power supply units are designed and developed for copper lasers and its variant delivering average electrical output power in the range of 1 kW to 10 kW.

Some power supply units incorporates advanced microcontroller units for monitoring and control of various parameters for the laser operation. The solid state pulse power supplies are upgraded with reliable and user-friendly PLC based control unit. Synchronization of solid state pulse power is achieved to operate the lasers in Master Oscillator Power Amplifier (MOPA) configuration. Some units / cards developed in the lab are:

- Timer Control Unit: A timer control unit is developed to generate control signals for three IGBTs. The dead time between the control signals and timing of pulses can be varied in the range of 5 µs to 75 µs for each channel. The unit is a plug in module of size 3U, 12T and can be operated in internal and external mode (glass fibre) of operation.

- Gas and Vacuum Control Unit

- Pressure and Temperature Monitoring Card

- IGBT driver Card : A dual channel IGBT driver card using driver IC M57962L is developed to drive IGBTs rated for 1200 V, 150 A to 400 A. The card requires +15 VDC for its operation.

- Precise delay generator Unit, 0 to 255 ns with resolution of 1 ns

- Programmable Logic Controller Unit for monitoring and control of Laser and DC power supply

Specifications of IGBT based solid state pulse power supply for 40 W Copper Vapour Laser

- Input: Three phase, 415 VAC mains, 50 Hz

- Output peak voltage: 25 kV

- Peak current: 900 A

- Pulse repetition rate: 6.5 kHzp

- Rise time: 80 ns

- Average output power: 5 kW

- Pulse generator topology: IGBT based capacitor to capacitor charge transfer circuit with MPC

- Cabinet size: 19” / 36U rack, 800mm depth

- Cooling: Water cooled

|

|

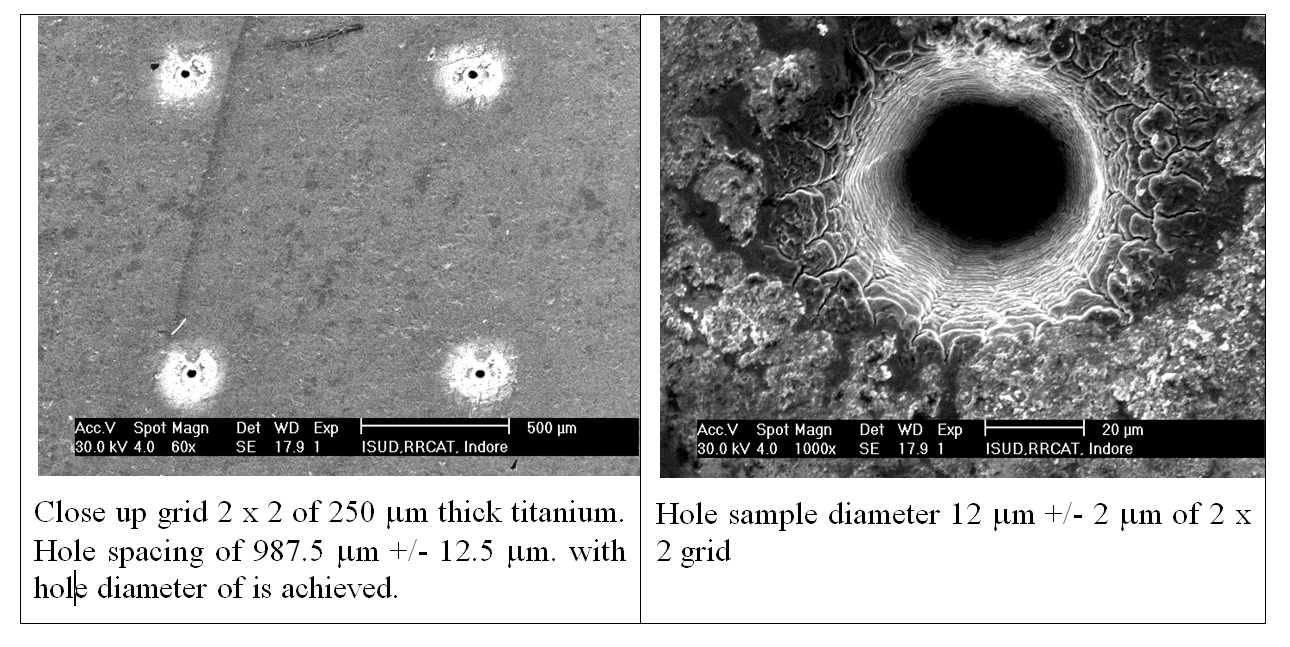

c) Application of copper vapor laser (Micromachining setup):

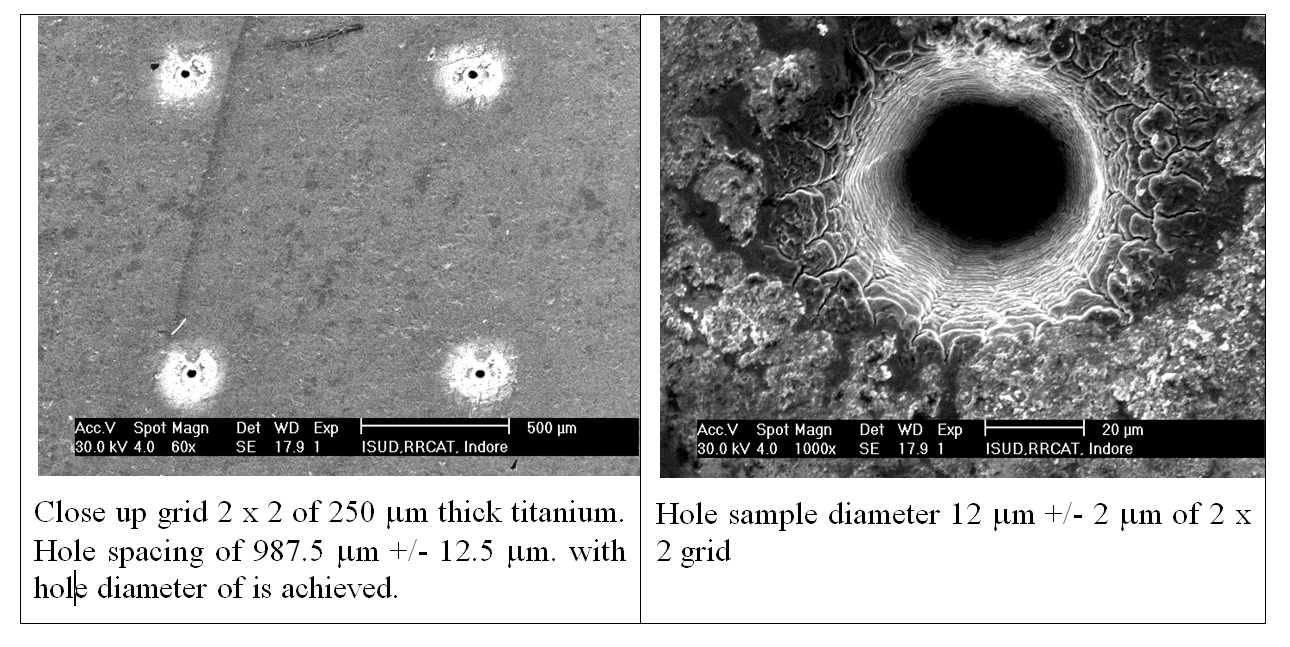

Copper vapor laser is used in application high end micromachining, a setup based on 1 oscillator and 1 amplifier is developed. The setup has precise movement of work piece mounted on X-Y table is controlled by PC with machine positional accuracy and repeatability of 10 µm. The maximum limit of two axis X-Y table is 420 mm X 420 mm. Depending on the power requirement the setup parameters like beam quality, output power, machine speed, focal length etc can be modified and material processing can be performed. Experiments like cutting, drilling, grooving, marking on different materials (Al, SS, Cu) of different thickness can be carried out. Some results of CVL micromachining are:

|