|

|

| Laser Materials Processing Division |

Nanostructured ZnO for piezoelectric mechanical vibration harvesting |

Reduction in size and energy demands of modern sensors and CMOS electronic circuitry in handheld mobile devices has opened a novel research area of developing suitable powering technologies from harvesting energy available from our living environment such as solar energy, thermoelectricity, and mechanical vibrations. Vibration-based mechanical energy is abundant in the environment and easily accessible than solar and thermal energy. Mechanical vibrations of frequencies from a few Hz to several kHz with available energy density ranging from a few hundred µW to mW/cm3 can be harvested using piezoelectric effect for battery recharge and even complete replacement of batteries in some cases. The piezoelectric materials directly convert mechanical energy into electricity which can potentially facilitate the continuous and adaptable operation of micro and nano-electronic devices and systems. Traditionally, the multi-component ceramic PbZrTiO3 and BaTiO3 have been the mostly used for mechanical energy harvesting applications. However, the major issues with piezoelectric generators based on conventional PbZrTiO3 and BaTiO3 ceramic thin films are high internal electrical losses and reliable contact potential barrier between the piezoelectric material and metal electrodes, which significantly reduce the conversion efficiency. These issues can be addressed by using a wide bandgap oxide semiconductor which is also piezoelectric. ZnO is one such semiconductor and due to its abundant availability, nontoxic nature and good piezoelectric properties it is one of the promising materials for this application. We have initiated research activity on developing schemes for vibration energy harvesting using ZnO nanostructures by exploiting its coupled piezoelectric and semiconducting characteristics for powering micro/nano electronic devices. For these studies nearly vertically aligned ZnO nano-rods have been grown using optimized pulsed laser deposition techniques. Detailed experimental studies on piezoelectric characteristics of nano-columnar ZnO thin films, nano-wires and nano-composites in different device geometries, role of contact barrier layer on conversion efficiency and use of flexible substrates (ITO coated PET) for better performance are under way.

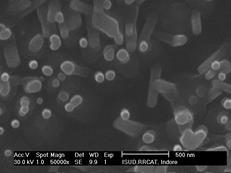

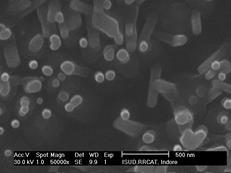

SEM image of ZnO nanowires grown by PLD |

|

|