|

|

| Laser Materials Processing Division |

|

Materials joining for in-house applications

|

Alumina-Alumina brazing for application in vacuum chambers of proton synchrotron

- Conventional route adopted for alumina-alumina brazing is: multi-step Mo-Mn metallization of faying alumina surfaces followed by their brazing with BVAg-8 alloy.

- Alternative joining approach is advanced single-step active brazing with CuSil-ABA alloy.

|

Table-1: Strength of brazed joints |

Brazing route |

Tensile strength |

Flexural strength |

Metallization |

35 MPa |

149 MPa |

Active brazing |

62 MPa |

110 MPa |

|

Highlights:

- The results of in-house study has demonstrated that active brazing is the simple and cost effective alternative to conventional metallization route for producing sound, strong, heremticaly sealed (helium leak rate ≤ 2 x 10-10 mbar.lit/s) and bakeable brazed joints.

Fig.1: Vacuum brazed alumina specimens. |

|

| |

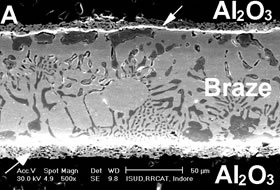

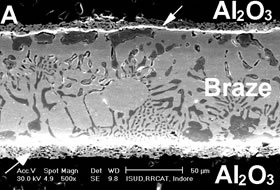

Fig.2: Cross-sections of vacuum brazed alumina specimens, prepared through (A) metallization and (B) active brazing routes. |

Publications: D. P. Yadav et al. Materials & Design, 64, 2014, 415-422.

|

| |

|

|