|

|

| Laser Materials Processing Division |

Laser surface treatment for enhanced fatigue and corrosion resistance

Suppression of stress corrosion cracking susceptibility of shear cut 304L stainless steel through laser shock peening

Objective:

- Shear cut surfaces of 304L SS, because of high magnitude of associated residual tensile stresses are prone to stress corrosion cracking (SCC) during storage in susceptible coastal environment.

- This experimental study aimed at suppressing high SCC susceptibility of shear cut surfaces of type 304L SS.

Highlights:

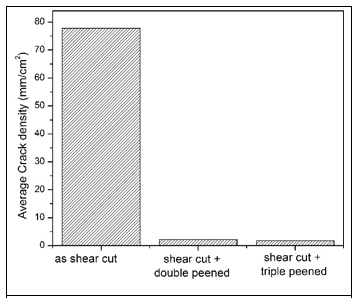

- Double and triple laser shock peening of shear cut type 304L SS sheet successfully transformed high magnitude of residual tensile stress present on as sheared surface into residual compressive surface stresses.

- Sheared surfaces, after laser shock peening, exhibited significantly reduced susceptibility for stress corrosion cracking in chloride environment (Fig.1).

Potential Applications:

The results are important for the product and components of austenitic SS with sheared cut surfaces stored in susceptible corrosive environment.

Fig.1: Average crack density (surface area = 1 cm2) on shear cut surfaces of type 304L SS specimens after their exposure to 8h long accelerated SCC test as per ASTM G36. |

Publication:R. K. Gupta et al., Paper No. CP-06-517, Proc. 29th DAE-BRNS (NLS-29), 2021.

Laser peening enhances surface defect tolerance of SAE9260 spring steel with respect to its fatigue life

- Presence of surface defects is known to adversely affect fatigue life of engineering components. These surface defects serve as potent stress raisers, thereby facilitating early nucleation of fatigue cracks.

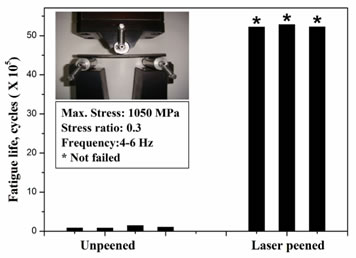

- A recent in-house study, performed on SAE 9260 spring steel, demonstrated that surface defects can be effectively made harmless by introducing compressive residual stress around the defect site through laser shock peening (LSP).

- Approach adopted: (i) introduction of reproducible defects on the surface of the specimens, (ii) LSP of the defect site and (iii) comparison of fatigue lives of laser peened and unpeened specimens (with surface defects).

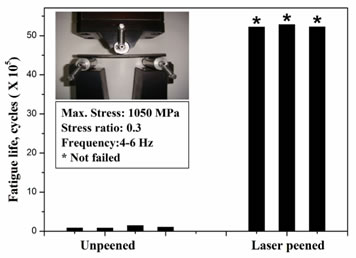

- Laser shock peening of defect site brought about significant increase in fatigue life of SAE 9260 spring steel specimens (refer Fig.1).

- The results are important for suppressing adverse effect of pre-existing surface defects on fatigue life of engineering components.

|

Fig. 1: Comparison of fatigue lives of unpeened and laser peened spring steel specimens with surface defect. Inset in the figure shows fatigue testing in 3-point bend configuration. |

|

Publication: RRCAT Newsletter, Vol. 31 Issue 1, 2018, page 26 |

|

|

Suppression of stress corrosion cracking (SCC) susceptibility of machined 304L stainless steel (SS) through normal and oblique laser shock peening (LSP)

- Machined surface of austenitic SS displays high susceptibility for SCC in susceptible corrosive environment. SCC is mostly noticed on internal surface of tubular components.

Highlights:

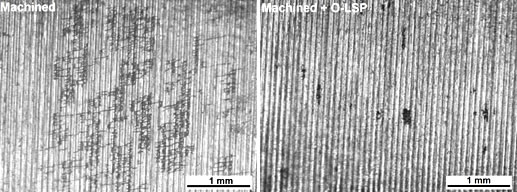

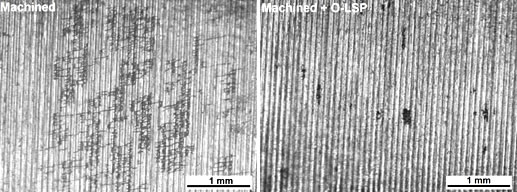

- SCC susceptibility of machined surface of 304L SS was strongly suppressed through LSP (Fig. 2).

- A new approach of oblique LSP has been exploited to suppress SCC susceptibility of machined internal surface of a 304L SS tube (OD = 111 mm; ID 101 mm) (Fig. 3).

Fig.2: Cracks on the surface of partly peened surface of machined & ground 304L SS specimens after accelerated SCC test in boiling MgCl2. (UP: unpeened; LP: laser peened) |

- Oblique LSP, with its limitation on length of peened region limited by tube ID and need for access from both sides, presents a simplified approach for peening internal surface of tubular components.

|

Fig.3: Cracks on internal machined surface 304L SS tube after accelerated SCC test in boiling MgCl2 (ASTM G36). |

Publication: R. Sundar et al., J. Mater. Eng. Perf., 25(9), 2016, 3710-3724. |

|

Enhancement of inter-granular corrosion (IGC) resistance of type 304 stainless steel (SS) through a new surface thermo-mechanical treatment (STMT)

IGC is one of the important degradation mechanism of austenitic SS components operating in corrosive environments. IGC is also responsible for “weld decay” in austenitic SS weldments.

Highlights:

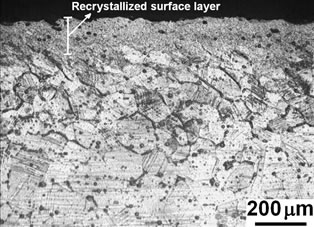

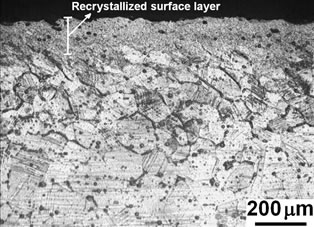

- A new STMT approach, combining conventional shot blasting and laser surface treatment, has been developed for enhancing IGC resistance of 304 SS. Modified surface displays fine re-crystallized austenite grains (Fig.4).

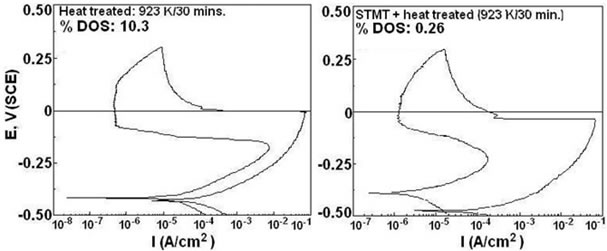

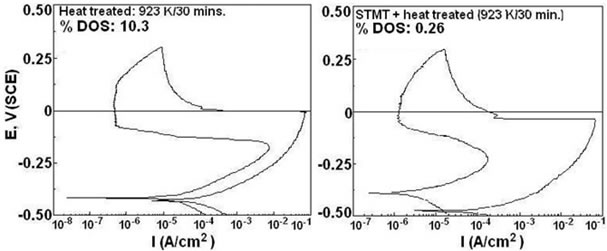

- Laser-assisted STMT of 304 SS effective in enhancing material's inherent resistance against sensitization & IGC (Fig.5).

- STMT is also effective in suppressing IGC susceptibility of pre-sensitized 304 SS specimens.

- STMT also enhanced material’s resistance against general corrosion & pitting.

|

Fig.4: Cross-section of surface thermo- mechanically treated 304 SS specimen.

Fig.4: Cross-section of surface thermo- mechanically treated 304 SS specimen.

|

|

Fig.5: Double-loop EPR plots of 304 SS specimens in (i) sensitized (923 K/30 mins.) and (ii) STMT + sensitized (923 K/30 mins.) conditions.

|

Publications:

- P. Ganesh et al., Surface & Coatings Technology, 232, 2013, 920-927.

- Anita Toppo et al., J. Mater. Engg. & Perf., 22(2), 2013, 632-639.

|

|

Suppression of inter-granular corrosion (IGC) susceptibility of type 304 stainless steel (SS) through laser shock peening (LSP)

Highlights:

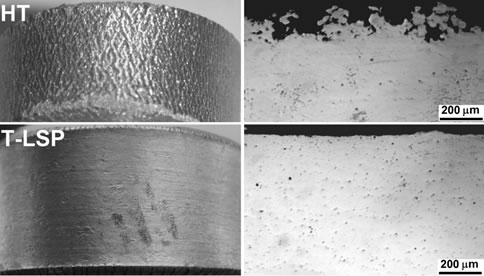

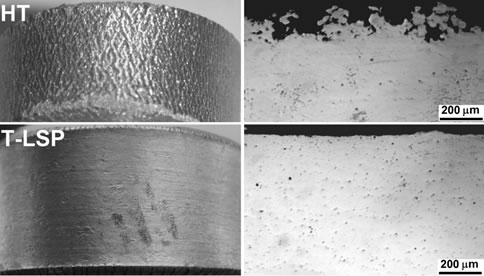

- LSP was used as a micro-structural modification tool to suppress IGC susceptibility of sensitized type 304 SS.

- IGC susceptibility of a sensitized 304 SS specimen underwent progressive reduction with an increase in the number of exposures to LSP treatments.

- Triple laser shock peening of sensitized 304 SS specimen brought about significant reduction in its IGC susceptibility (Fig.6).

- Improved IGC behaviour of triple laser peened sensitized SS specimen is attributed to breakage of inter-granular network of chromium carbide/Cr-depleted regions under the influence of high strain rate plastic deformation imposed by LSP.

Potential application: Results are important for enhancing IGC resistance of austenitic SS weldments without resorting to solution annealing treatment which may otherwise introduce unwanted distortion in the component.

Fig.6: ASTM A262 practice E tested (i) sensitized (HT) and (ii) sensitized + triple laser peened (T-LSP) 304 SS specimens and their cross-sections.

Publication: R. K. Gupta et al., Corrosion Engineering, Science and Technology, 52(3), 220–225, 2017.

|

|

|