|

Beamline overview

Material investigations under extreme conditions (high pressure/ temperature) provide vital information about microscopic interactions through structural evolution and/or realization of new phases which may have unusual properties. To serve this purpose, the in-situ structural determinations under extreme conditions are primarily performed using x-ray diffraction (XRD), a versatile non-destructive technique. There are two main variants of x-ray diffraction technique viz. angle dispersive x-ray diffraction (ADXRD) and energy dispersive x-ray diffraction (EDXRD). Both the techniques have their own merits. EDXRD technique is advantageous in case of constrained geometries and kinetics investigations whereas ADXRD provides high resolution diffraction data for detailed structural refinement. An ED/AD-XRD beam line, incorporating both these variants and especially optimized for material investigations under extreme conditions has been developed and commissioned at port no. BL-11. This beam line is being routinely used by several national and international users.

Beamline specifications

| |

EDXRD |

ADXRD |

| SR source: |

Bending Magnet 1.5T |

Bending Magnet 1.5T |

| Energy range: |

10-70 KeV @ 2.5 GeV, 300 mA |

Monochromatic tunable

10 Kev to 30 KeV

|

| Angular range for diffraction |

±25° |

Depends on sample to detector distance, typically ± 45 °

|

| Q Range: |

1.3 to 15 Å-1 (for 2θ =25° ) |

~Up to 12 Å-1 at 30 keV

|

| Detector resolution |

145 eV at 5.9 KeV; 475 eV at 122 KeV |

Mar345 area detetctor with 0.1 * 0.1 mm2 pixel

|

| Resolution |

2% (Geometrical) |

4.7 * 10-4 @ 17 KeV (calculated)

|

| Spot size at sample |

~100*100 μm (which can be increased up to 5*5 mm) |

~ 50x30 μm (using compound refractive lens)

|

| Total Flux at sample |

1011 photons/s (for 300 mA @ 2.5 GeV and 100*100 μm spot size) |

1010 photons/s (for 300 mA @ 2.5 GeV and 1x1 mm2 spot size)

|

Experimental setup

The front end for the Extreme conditions ED/AD-XRD beamline delivers a 1 mrad white beam. This beam is transported to the experimental station through various components viz. beam stopper, primary slit and precision slit. Primary slit and precision slit cut down the size of synchrotron radiation (SR) to 100μm * 100μm at the sample. There are two variants at the experimental station viz. the EDXRD variant and the ADXRD variant.

1) EDXRD variant

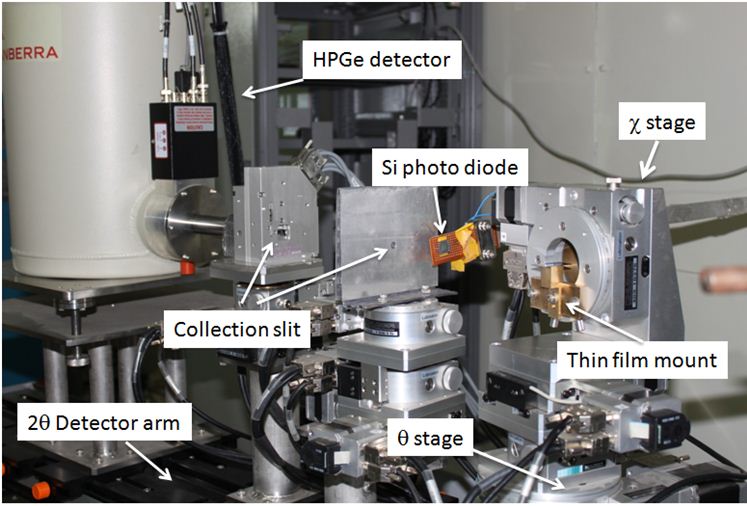

A custom made 8-axis sample stage goniometer from Huber is installed for sample mounting. This goniometer has maneuverability of XYZ translation, rotation and tilt. The data acquisition system comprises of a high resolution HPGe detector mounted on a detector arm attached to the 2θ stage of the goniometer. The detector is preceded by a cleaning slit and a point slit. Diffraction angle is defined by cleaning slit and point slit within the precision of ~0.001°. Cleaning slit also helps in reducing the background arising from the Compton scattered x-rays. Main features of EDXRD variant are tabulated below.

8 axis motorized goniometric stage |

Bottom XY- stage ; Θ-2Θ stage; Sample XYZΧ stage |

2Θ detector arm with travel range ±25° |

Detector: High Purity Ge detector |

|

Fig. EDXRD variant at BL-11 |

2) ADXRD variant

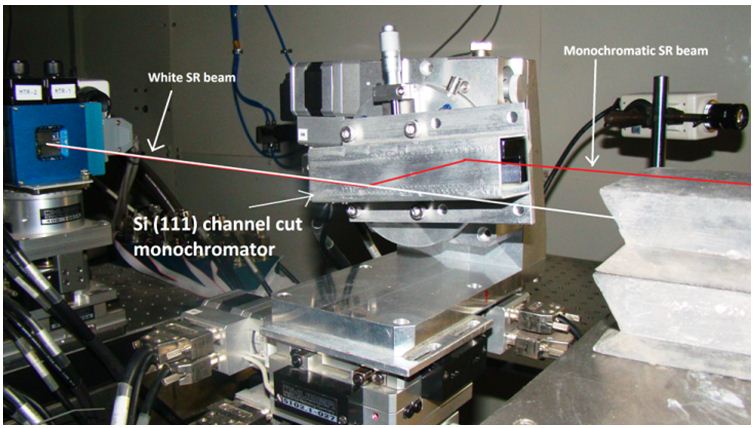

To complement the utilization of EDXRD beamline, it has been adapted for ADXRD measurements. This has been achieved by monochromatizing white synchrotron beam using Si (111) channel cut monochromator. This adaptation has been ergonomically conceived using the existing infrastructure at the beam line and switching between the two variants is easily achieved. In order to avoid diffraction peaks from gasket material used for high pressure measurements, a compound refractive lens (CRL) based micro-focusing arrangement has also been incorporated at the beamline. These CRL's have been indigenously developed at x-ray lithography (BL-7) of INDUS-2 synchrotron source.

|

Fig. Monochromatization using single crystal Si (111) channel cut monochromator

|

|

Fig. Micro-focusing using indigenously developed Compound refractive lens (CRL)

|

|

Fig. Diffraction image collection at MAR345 imaging plate

|

Beamline capabilities

- Energy dispersive x-ray diffraction measurements

- High pressure powder diffraction (Up to Megabar)

- High temperature powder diffraction (inside capillary up to 1500° K)

- Energy dispersive grazing incidence x-ray diffraction

- Ambient and High temperature (up to 700°K)

- Angle dispersive x-ray diffraction

- High pressure powder diffraction (Up to Megabar)

- High pressure single crystal diffraction

- High temperature powder diffraction (inside capillary up to 1500° K)

- Total x-ray scattering measurements for pair distribution function analysis

|

Fig. Grazing incidence EDX adaptation for thin films

|

|

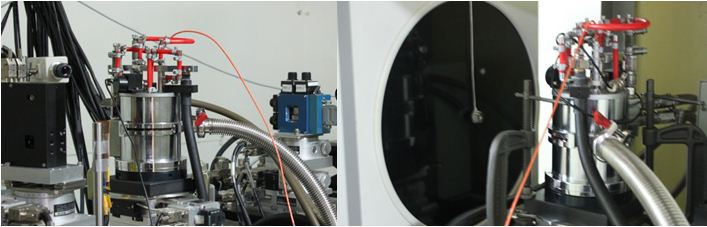

Fig. Adaptation of ED/ADXRD setup for high temperature measurement up to 1500° K

|

|

Fig. Off-line ruby pressure measurement setup

|

A few recent studies performed using BL-11

-

High pressure study on α⇔ω⇔β transition sequence in several pure and impure samples of Hf metal

Journal of Applied Physics, 115, 233513 (2014)

|

Fig. Evolution of volume fraction of alpha, omega and beta phases of Hf as a function of pressures

|

-

Ex-situ in-plane and out-of-plane diffraction measurements revealing the growth of Co on oxidized interface with preferential orientation of c-axis perpendicular to the film plane

Journal of Physics D: Applied Physics, 47, 105002 (2014)

|

Fig. Grazing incidence x-ray diffraction of Co/CoO/Co thin film

|

-

Stability of ambient rhombohedral structure of CuCrO2 upto ~ 23 GPa however with large anisotropy in axial compression with c-axis compressibility, kc = 1.26 * 10-3 GPa-1 and a-axis compressibility, ka = 8.9 * 10-3 GPa-1

Journal of Applied Physics, 116, 133514 (2014).

)

|

Fig. Evolution of lattice parameters of CuCrO2 as a function of pressure.

|

-

X-ray diffraction studies confirm two phase transformations in NaZr2(PO4)3 around 5 and 6.6 GPa conjectured through Raman scattering measurements

Journal of Solid State Chemistry, 221,285-290 (2015).

)

|

Fig. Structural transition in NaZr2(PO4)3

|

|

Fig. Equation of state of different phases of NaZr2(PO4)3

|

Publications related to Bl-11

Peer reviewed journal articles:

- Energy dispersive x-ray diffraction beamline at Indus-2 Synchrotron source;

K. K. Pandey, H. K. Poswal, A. K. Mishra et. al; Pramana –

J. Phys., Vol. 80, No. 4,607-619 (2013).

- In-situ energy dispersive x-ray diffraction study of the growth of CuO nanowires by annealing method;

H Srivastava, T Ganguli, SK Deb, T Sant, HK Poswal, SM Sharma;

Journal of Applied Physics 114(14), 144303 (2013).

- Influence of ion-to-atom ratio on the microstructure of evaporated molybdenum thin films grown using low energy argon ions;

Praveen Kumar Yadav, Tushar Sant, Chandrachur Mukherjee, Maheswar Nayak, Sanjay Kumar Rai, Gyanendra Singh Lodha and Surinder Mohan Sharma;

J. Vac. Sci. Technol. A 32, 021509 (2014).

- Interface induced perpendicular magnetic anisotropy in Co/CoO/Co thin film structure: An in-situ MOKE investigation ;

Dileep Kumar, Ajay Gupta, P. Patidar, K.K Pandey, T. Sant and Surinder M. Sharma;

Journal of Physics D: Applied Physics, 47, 105002 (2014).

- Reinvestigation of high pressure polymorphism in Hafnium metal;

K. K. Pandey, Jyoti Gyanchandani, M. Somayazulu, G. K. Dey, Surinder M. Sharma and S. K. Sikka;

Journal of Applied Physics, 115, 233513 (2014).

- Multiferroic CuCrO2 under high pressure: In situ X-ray diffraction and Raman spectroscopic studies;

Alka B. Garg, A. K. Mishra, K. K. Pandey and Surinder M. Sharma;

Journal of Applied Physics, 116, 133514 (2014).

- Pressure induced phase transformations in NaZr2(PO4)3 studied by X-Ray diffraction and Raman spectroscopy ;

K. Kamali, T. R. Ravindran, N. V. Chandra Shekar, K. K. Pandey, S. M. Sharma;

Journal of Solid State Chemistry, 221,285-290 (2015).

Conference proceedings:

- Energy Dispersive X-ray Diffraction Beamline at Indus-2 Synchrotron Source;

H. K. Poswal, K. K. Pandey, A. K. Mishra, et. al.;

BARC news Letters (founder’s day issue), (2011).

- High Pressure phase transitions in Nd2O3;

K.K. Pandey, Nandini Garg and Surinder M. Sharma;

147, AIRAPT-23(2011).

- GIXRD Measurements at EDXRD beamline at Indus-2 Synchrotron;

K. K. Pandey, Dileep Kumar, Abhilash Dwivedi, Ajay Gupta and Surinder M. Sharma;

AIP conference proceedings 1447,483 (2012).

- Textured Growth of Co on CoO (fcc) layer; structural studies at EDXRD Beamline INDUS-2, RRCAT;

Dileep Kumar, Tushar Sant, K. K. Pandey, Ajay Gupta and Surinder M. Sharma,

AIP conference proceedings 1447,721 (2012).

- Oxidized interface induced perpendicular magnetic anisotropy in Co/CoO/Co thin film

structure; Dileep Kumar, P. Patidar, A. Gupta, T. Sant et al.;

12th international SXNS (2012).

- Depth sensitive structural information of thin films from energy dispersive grazing incidence diffraction;

T. P. Sant, K. K. Pandey, Dileep Kumar, Surinder M. Sharma;

12th international SXNS (2012).

- High pressure phase transition in Nd2O3;

K. K. Pandey, Nandini Garg, A. K. Mishra and Surinder M. Sharma;

Journal of Physics: Conference Series 377, 012006 (2012).

- In-situ study of the growth of CuO nanowires by energy dispersive X-ray diffraction;

H. Srivastava, T. Ganguli, S.K.Deb, T. Sant, H.K. Poswal, Surnider M. Sharma;

AIP Conference Proceedings, 1512, 306-307 (2013).

Contact Number : 244 2511

Contacts:

|