| Accelerator Controls & Beam Diagnostics Division |

| Control System for Proton Linac Sub-systems |

| |

H- ion Source Control System

A prototype filament based multi-cusp H- ion source has been developed at RRCAT and successfully operated

in c.w. mode to extract H- ion beam at 30 kV with beam current of 52 µA.

The H-ion source control system controls and monitors various signals like gas flow, power supply current and

voltage, timing delays and width etc. For this different types of devices have been interfaced to the control system.

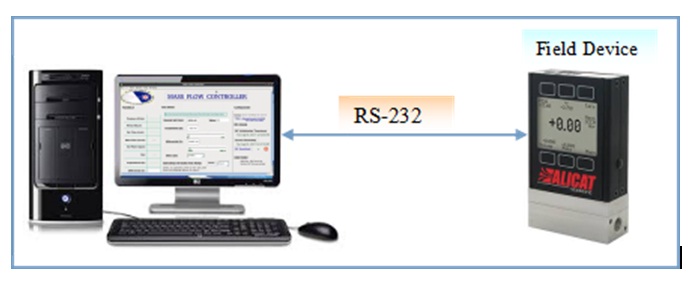

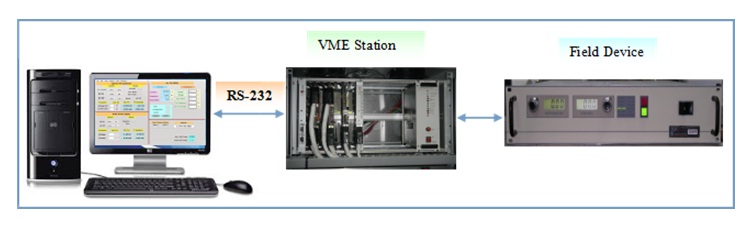

Fig: System in the field

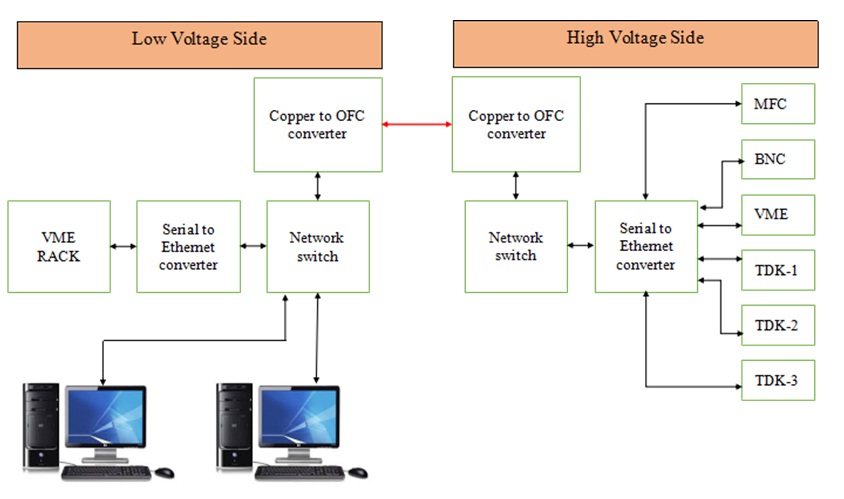

Fig: The architecture of the overall system

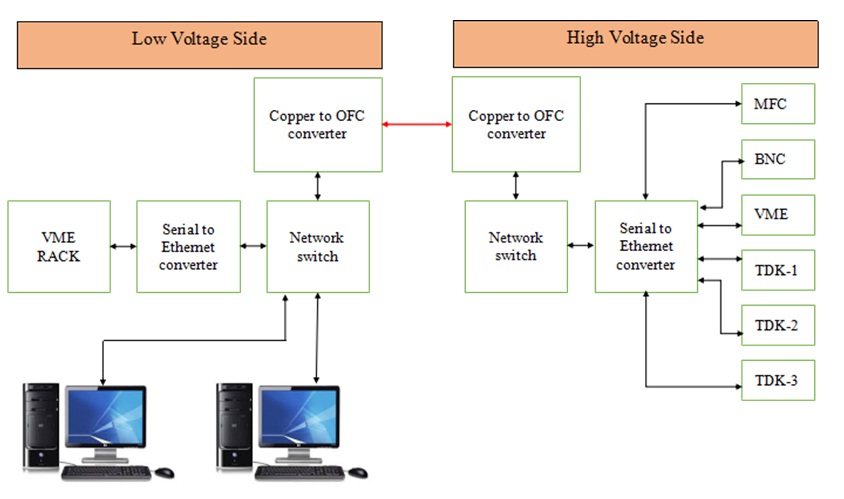

Architecture of Control System:

The Control System for H- ion source has following two topologies:

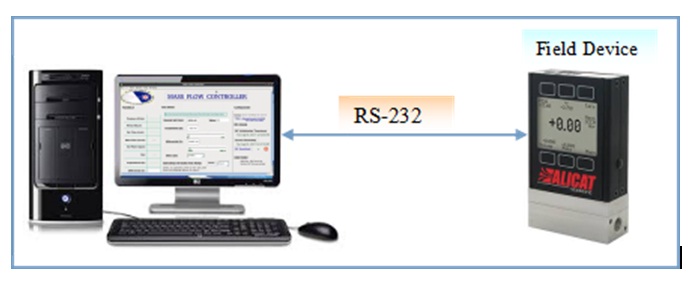

1. Serial Interface to Instruments

The software running on PC directly communicates with the device over RS-232/ RS-485 serial interface. There are various

devices like VME system, Mass Flow Controller (MFC), TDK Power Supplies, Synchronization Pulse Generator (BNC) etc.

|

|

| Fig: Serial Interface to Instruments |

| |

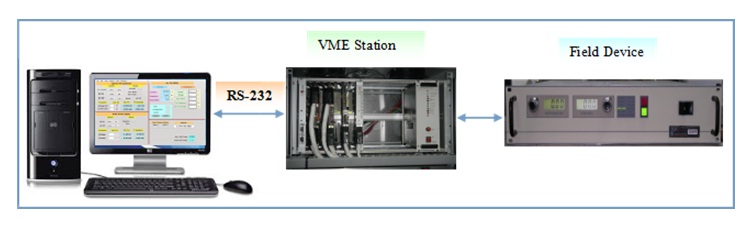

2. VME based 2-Layer system

- Layer-1 has PC with SCADA software built using EPICS.

- Layer-2 has two number of VME stations which has analog and digital interfaces with various instruments.

One of the VME stations is on the floating side (ground raised to -50KV) and the other is on the grounded side.

Layer-1 PC and Layer-2 VME stations communicate over RS-232.

|

|

| Fig: VME based 2-Layer system |

| |

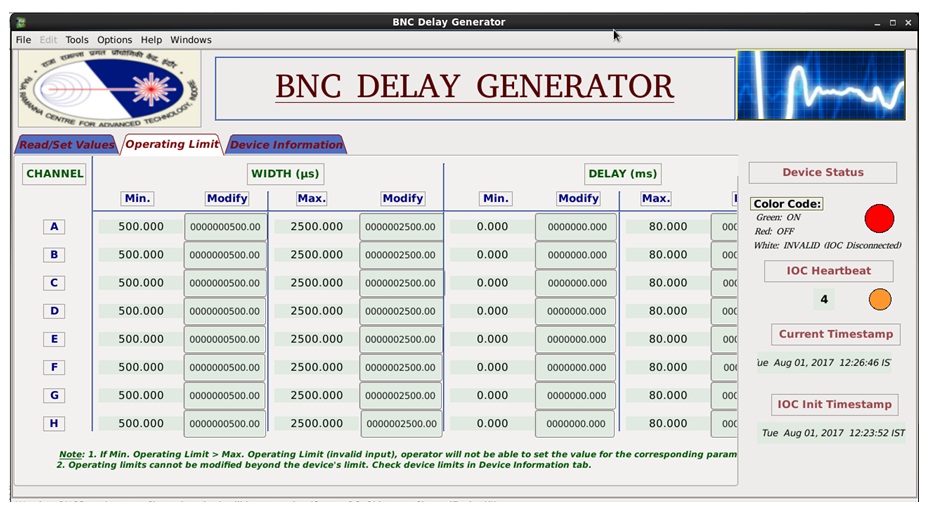

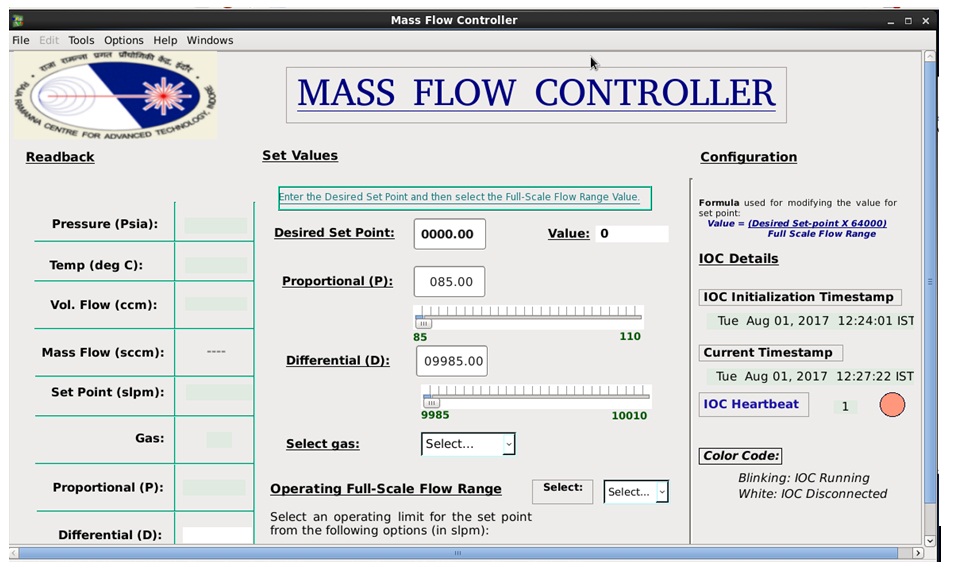

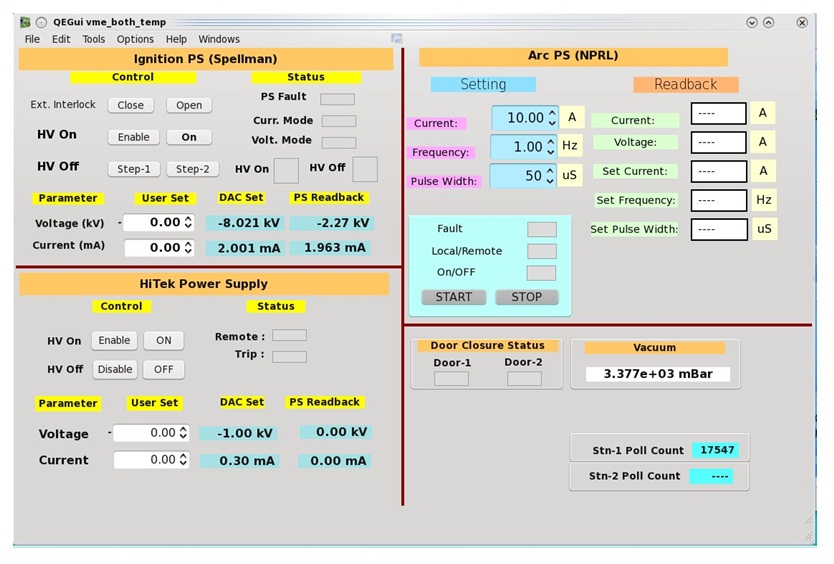

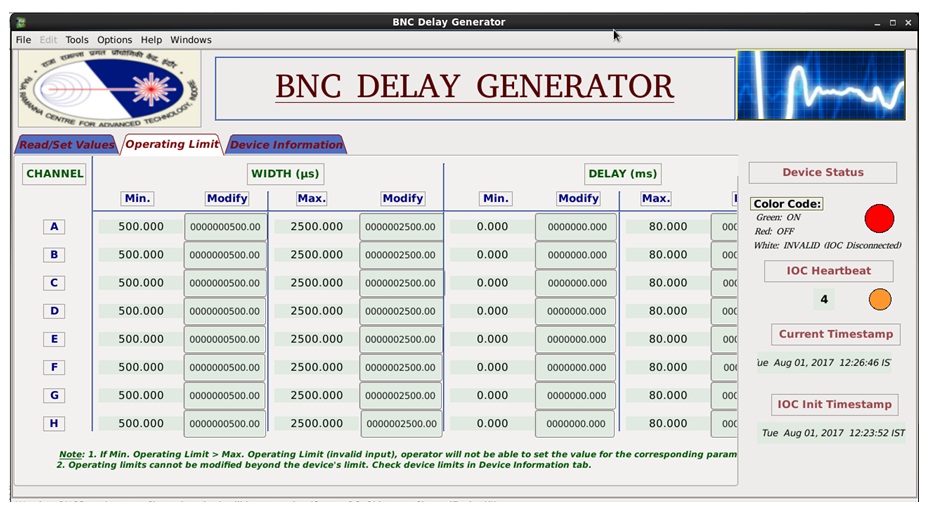

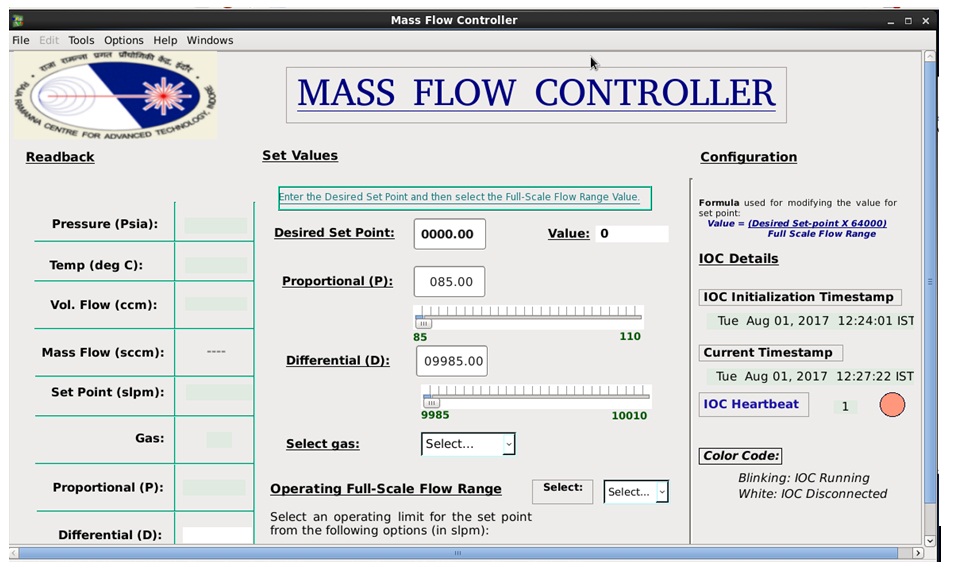

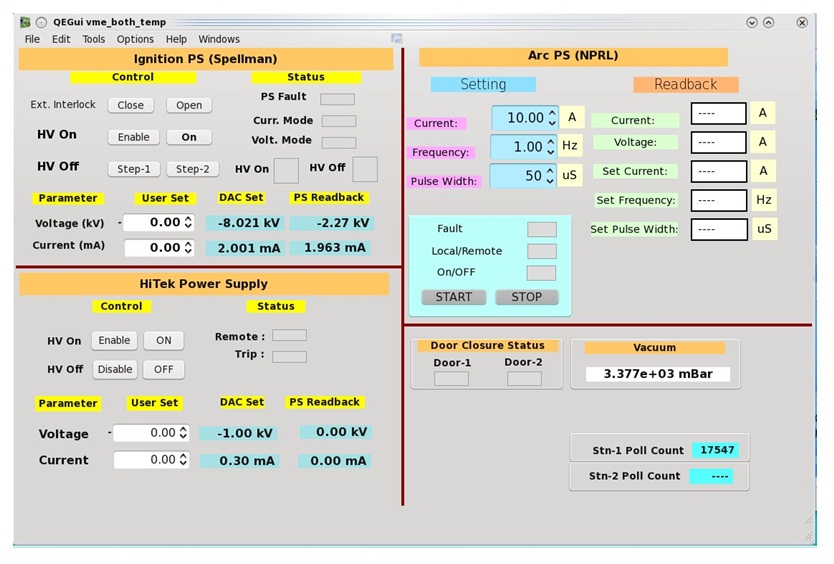

EPICS Software for Interfacing and Operator Panels

H-Ion Control system software is EPICS based. Each device interface has an IOC and an OPI to display controls and status values. The OPI is designed using EPICS-QT. The IOC and OPI can run independent of each other.

|

|

| Fig : BNC Delay Generator |

| |

|

| Fig : Mass Flow Controller |

| |

|

| Fig : GUI |

| |

|