| Accelerator Controls & Beam Diagnostics Division |

|

Communication Boards

Field Bus Controller Board

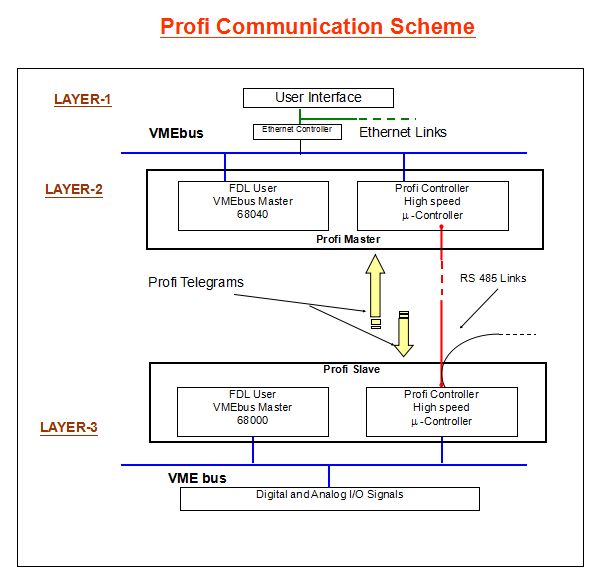

Accelerators environment demands fast and reliable information transfer using transmission protocols that have high data integrity and transmission efficiency with simple error detection and correction. This necessitates the use of Field Bus. We have chosen to use PROFI bus as the field-bus as it is a vendor independent, versatile communication standard supporting a wide range of applications. PROFI bus supports three layers of OSI reference model.

|

- Physical Layer

- Data Link Layer

- Application Layer

|

| Physical Layer |

|

It has been implemented using RS-485 as the transmission medium. It has been checked for baud rates from 9.6 Kbps to 345 Kbps and can support up to 1 Mbps. and application layer.

|

| |

| Data Link Layer

|

|

A VME-Based Micro controller board using Dallas 80C320 is used to implement the Data Link Layer of PROFI Bus called as FDL Controller. It handles the telegram (packets) communication on the bus with appropriate error checking and thus implementing the various services of the protocol.

|

| |

| Application Layer

|

|

Application Layer of PROFI-Bus comprises of a VME- Based Motorola 680X0 Board on which programs for Real Time Operating System OS-9 run. There are programs which uses the various services provided by the FDL Controller and communicate with other I/O modules on the VMEbus which are interfaced to the field equipments.

|

| |

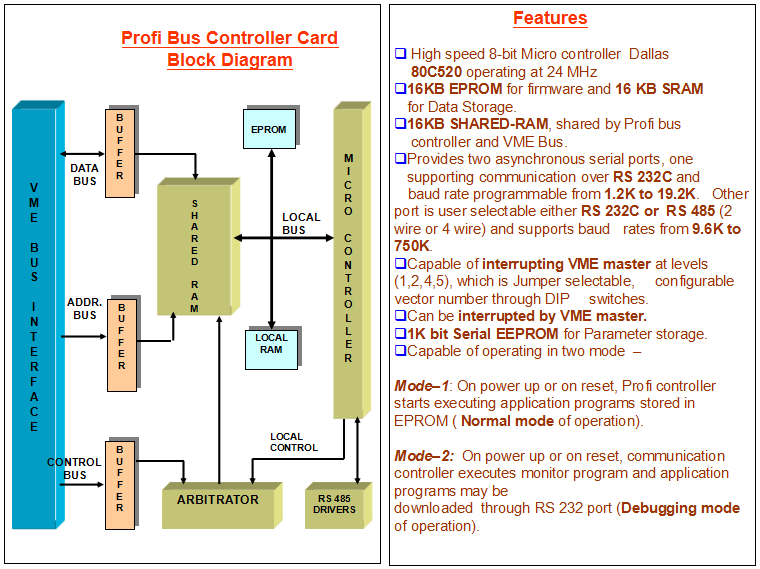

Salient Features of Field Bus Controller Board

- Intelligent controller for field bus implementation

- 16 KB shared RAM

- 16 KB SRAM

- 16 KB Firmware

- Two Serail Ports: RS 232 & RS 485

- Capable of interrupting VME master

- Address selection through DIP switches

|

|

|

Best viewed in 1024x768 resolution

|