|

Major Research Areas

R&D on GaAs based PIN photodetectors for customized applications in DAE

Radiation hard photodetectors are important for various

applications in the harsh environment of high temperature,

high pressure, and high radiation zones. In this context, the

technology for the fabrication of radiation hard GaAs based

p-i-n (PIN) photodetectors has been developed at RRCAT.

The devices work in the wavelength range of 325 to 870 nm

with a maximum responsivity of ~ 0.58 A/W along with a dark

current of < 1 nA and can detect very weak signals of 2 nW

power. Recently, a few customized detector systems are

deployed in field applications, where photodetectors and

necessary front-end electronics are made as per the user

requirements. An early arc detection system as a safety device

is deployed in an indigenously developed radio frequency

circulator at RRCAT. Further, a dual element photodetector

unit, consisting of two identical photodetectors on a chip, is

developed for laser spectroscopy experiments at RRCAT.

Radiation hardness of GaAs photodetectors is tested by

exposing the devices to 60Co g-radiation sources and is found

to be an order of magnitude higher when compared with

commercially available silicon photodetectors.

1. Introduction

Semiconductor photodetectors are an integral part of several

complex systems and find many interesting applications in

the modern life [1-2]. In these devices, the detection of

photons is governed by an effective collection of photogenerated

electron-hole pairs [3-4]. An illumination of a

semiconductor material with photons having energy larger

than the bandgap injects electrons in the conduction band

while leaving a hole in the valence band. Subsequently, the

photo-generated electrons and holes drift in opposite

directions under the influence of either built-in (internal) or

external electric field. Separation of electrons and holes via

this process gives rise to current flow across the device in a

closed-circuit configuration. Here, the magnitude of photo

current depends on the intensity of photon flux, absorption

coefficient of semiconductor material, and quantum

efficiency of the device. In order to have an internal built-in

electric field, several configurations of the structures are

being used. Semiconductor photodetector structures are

designed and developed in many configurations such as

Schottky, p-n and p-i-n (PIN) junction etc. The advantage of

PIN junction configuration is associated with a large depletion width, which results in higher quantum efficiency. A

wide depletion region leads to relatively small capacitance

which results in high bandwidth of detection. Semiconductor

junctions are engineered via an extreme control of dopant

density profile during the epitaxial growth. Out of all the

semiconductor materials, III-V compound semiconductors

have been used to develop key optoelectronic devices for a

variety of conventional and advanced applications over a

wide wavelength range varying from infrared to x-ray region

[3-10]. A few latest breakthroughs have spurred the

development of novel devices by keeping a major focus on the

improvement of peak responsivity, and also the radiation

hardness. GaAs, CdTe, InP, GaN, SiC semiconductor

materials offer higher radiation tolerance against ã-rays,

electrons, protons, and neutrons and can work in harsh

environments over extended durations [7-19] as compared to

Si or Ge. However, in India, fabrication of compound

semiconductor devices is limited to a few R & D labs and a

majority of these devices are being imported even today.

Semiconductor Materials Laboratory at RRCAT have been

working in this area for the last two decades where a major

emphasis is given on R&D of advanced light emitters and

detectors based on conventional group III-V and III-N

compound semiconductors. In this article, salient features of

the fabrication technology of GaAs based PIN photodetectors

are described including the relevant basic physics. Key

parameters asserting the state-of-the-art performance of

indigenously developed devices are also reported.

Representative applications of the devices are highlighted by

providing results from a few experiments. Details of a few

customized detector systems that are fabricated as per the user

requirements are also given. Radiation hardness of these

devices against the exposure to 60Co g-radiation sources is also

discussed.

2. Experimental details

Fabrication procedure of GaAs based PIN photodetectors is

described in this section. It includes epitaxial growth of

multilayer structure, and various devices fabrication steps like

photolithography, metallization, device isolation,

passivation, annealing, wire bonding, packaging, and device

testing.

2.1 Layer structure and growth conditions

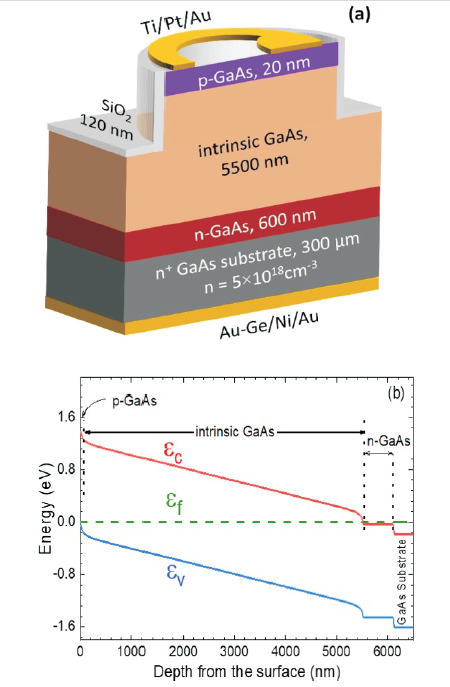

The typical layer structure of PIN photodetector consists of an

undoped 5.5 μm thick intrinsic (i-type) layer of GaAs

sandwiched between 20 nm of p-type (~ 2x1018 cm3) and 600

nm of n-type (1x1018 cm3) GaAs layers as shown in Figure

T.4.1(a). Numerically calculated energy band profile of the

photodetector structure is shown in Figure T.4.1(b). In a few

devices, internal gain layers are also embedded in the intrinsic

region of device. GaAs based multilayer structures are epitaxially grown by AIX-200 metal-organic vapor phase

epitaxy (MOVPE) system on 2-inch diameter n+-GaAs

substrates in the temperature range of 600-700 ºC. Tri-methyl

gallium and arsine are used as the precursors while silane and

diethylzinc are used for n and p-type doping respectively.

Each layer of the multilayer stack is individually optimized

with respect to the dopant density, whereas crystalline quality

is optimized by growing an undoped GaAs layer under

different growth conditions. A few calibration growth runs are

therefore needed prior to the epitaxial growth of complete PIN

photodiode structure.

(a) Schematic cross sectional view, and (b) energy

band profile of GaAs p-i-n photodetector

2.2 Device fabrication

After epitaxial growth, fabrication of semiconductor

photodetectors is performed by implementing several device

processing steps. First, Au-Ge/Ni/Au multilayer contacts are

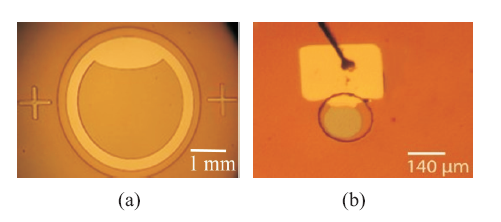

Photographs of GaAs photodetector element

having a diameter of (a) 3 mm, and(b) 100 µm

deposited on the backside of n+-GaAs substrate by thermal

evaporation technique, which is then followed by rapid

thermal annealing (RTA) at 375 ºC for 45 s under nitrogen

environment. Second, the active area of photodetector is

defined through photolithography step. Here, photoresist

(Shipley S1813) is coated on the top of epitaxial structure with

the help of a spin coater. The sample is then exposed to an

ultra-violet beam for a given duration which is then processed

for defining the active area of device. Third, a controlled

chemical etching of epitaxial structure is performed by

dipping the sample in CH3(OH):H3PO4:H2O2(6:3:1) solution

for 10 s at 35 ºC. It helps in defining the active area of device.

Fourth, a layer of SiO with thickness of ~120 nm is deposited 2

on the sample by electron beam evaporation technique [20-

22]. This helps in the passivation of surface states and also in

minimizing the reflection of photons from the detector

surface. Fifth, second photolithography step is performed to

define the top-contact area. Sixth, selective area oxide

removal is carried out by dipping the sample in buffer HF

solution, which therefore provides direct access to p-GaAs

layer in the defined region for the deposition of top-contact as

shown in Figure T.4.1(a). Seventh, Ti/Pt/Au multilayers are

deposited on the designed pattern on the top of the detector

structure, which is then followed by a metal liftoff procedure

and rapid thermal annealing. At the end of seventh step,

fabrication of individual detector element is completed.

Photograph of a large area photodetector element is shown in

Figure T.4.2(a), while that of a 100 mm diameter one is shown

in Figure T.4.2(b). Eight, the detector chip is die attached with

the help of silver epoxy on Au-plated copper mounts, which

provides the back contact. Ninth, 1 mil (~25 m) thick Au wire

is bonded to the front contact by ball-wedge bonding

procedure. It completes the fabrication of photodetector

device which is ready for mounting in specially designed

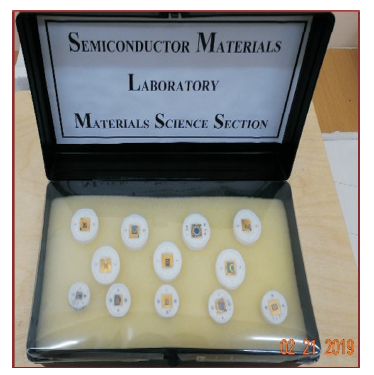

detector headers as per the requirement of user. Photograph of

12 numbers of GaAs PIN photodetectors with size varying

from 100µmm to 6 mm diameter is shown in Figure T.4.3.

These detectors are mounted in the indigenously designed device headers. Some of the fabrication steps had to be

customized in order to meet the user requirements that often

vary depending on the complexity of application. One critical

step is to define the size of detector element which is

application specific. For example, for low dark current

applications, a small element size (100 mm or lower) is

preferred. On the other hand, large area photodetectors are

generally preferred by most of the users. In some cases, a very

specialized geometry of detector element is preferred by the

user. One such example from laser spectroscopy is discussed

in the later part of the article. In conventional fabrication

route, one requires a new set of masks for photolithography,

whenever a change in the geometry of detector element is

sought by the user. It is quite inconvenient, since it not only

requires extra funds and time but also discourages newer

developments. Keeping this in mind, a low cost mask-less

photolithography setup is made and is currently being used in

the development of novel semiconductor devices on routine

basis. It is developed by using a digital-projector and a stereozoom

optical microscope [23].

Photograph of 12 numbers of GaAs PIN

photodetectors with element size varying from 100 mm to 6

2.3 Device testing

Operating performance of the devices needs to be checked

through various characterization procedures before their

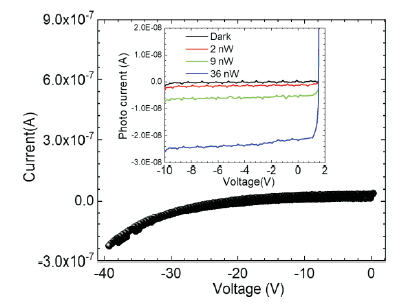

deployment in field applications. Figure T.4.4 shows the

representative current-voltage characteristics of a

photodetector with 5 mm diameter which can be biased upto

-40 V. For low dark current applications, a specific structure

with internal gain is designed and the performance of such a

device having 3 mm diameter is shown in the inset of Figure

T.4.4 [24]. It is obvious from the inset that the dark current

increases from 5 pA to 2 nA under light exposure. It is also

shown that the device can read laser power down to 2 nW.

Current-Voltage characteristics of indigenously

developed GaAs photodetector. Inset shows variation in the

reverse saturation photocurrent of a specially designed

device under light exposure at 730 nm.

Next, the responsivity (R) of photodetectors is estimated by

using the relation, R=JA/Pin , where J is photocurrent density, in

A is area of detector element, and Pin is the power of incident in

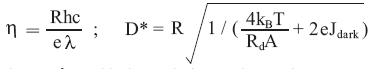

light. Quantum efficiency (η) and specific detectivity (D*) of

the device are also estimated by using the following

expressions [24-25];

where, h, c, e, λ, and kB have their usual meaning, Rd stands for B d

the dynamic resistance of device, T is temperature in kelvin

and Jdark is the dark current at temperature T. It may be noted dark

that the value of D* might change slightly after including the

generation–recombination process in the active region of the

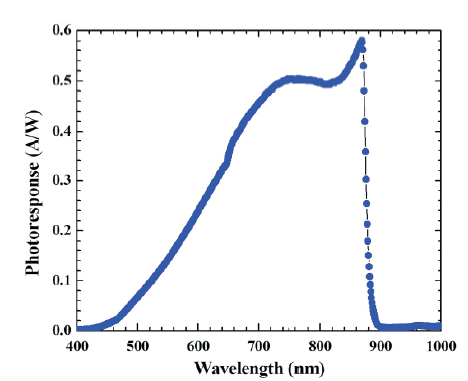

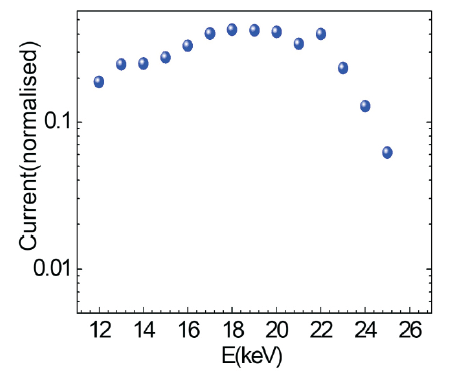

device. Further, the spectral response of photodetectors is

shown in Figure T.4.5. The detector works in the wavelength

range of 325 to 870 nm with a maximum responsivity of

~ 0.58 A/W at 869 nm and the dark current remains < 1 nA

even for devices having large diameter approaching 10 mm.

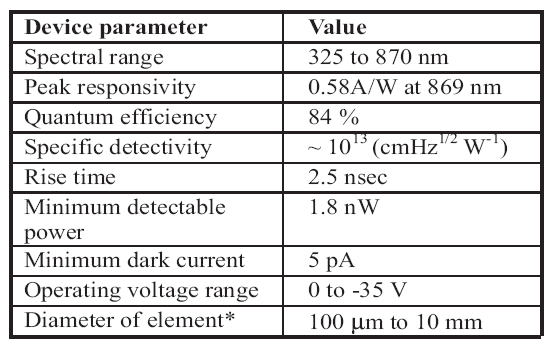

The operating characteristics of indigenously developed

photodetectors are summarized in Table T.4.1. These are the

best set of parameters achieved for the indigenously

developed devices, which certifies a state-of-the-art

performance of GaAs PIN photodetectors. It is needless to say

that particular device characteristics can be fine-tuned as per

the user requirement, including the range of spectral response,

which can be tailored by growing a different heterostructure

by MOVPE.

Spectral response of indigenously developed GaAs photodetector.

Operating characteristics of indigenously

developed GaAs photodetectors

* Diameter of detector element can be varied as per the user

requirement.

3. Deployment of indigenously developed GaAs PIN

photodetectors

Excellent operating characteristics of indigenously

developed devices as shown in Table T.4.1 encouraged us to

look for their possible applications in the departmental work.

A brief summary of the deployment of indigenously

developed GaAs PIN photodetectors is given in this section.

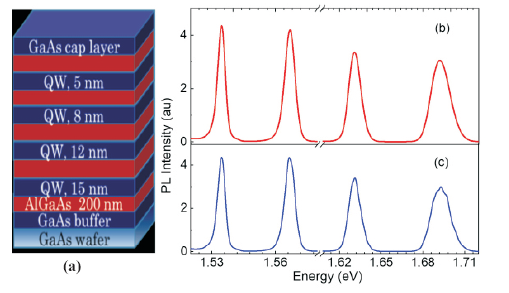

3.1 Application in photoluminescence spectroscopy

Photoluminescence (PL) spectroscopy is a standard method

to characterize the optical quality of epitaxial layers. A strong

PL signal indicates better crystalline quality of the material

under investigation. GaAs PIN photodetectors are used for

measuring the PL spectra of various quantum well (QW)

samples grown in our lab. Figure T.4.6(a) shows the

schematic layer structure of a multi QW structure which is used as a test sample. PL spectrum of this sample is recorded

with the help of a commercially available Si photodetector,

and also with an indigenously developed GaAs photodetector.

The outcome of such an exercise is shown in Figure T.4.6. It

certifies the usefulness of developed devices in PL

spectroscopy.

(a) Schematic layer structures of a multi quantum

well structure, and PL spectra of sample recorded with (b)

commercially available Si photodetector, (c) indigenously

developed GaAs photodetector.

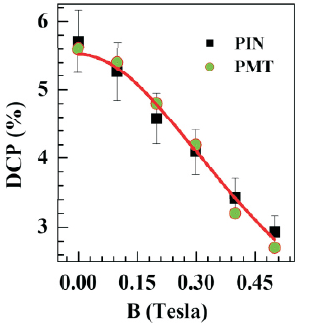

3.2 Detection of degree of circular polarization of PL

Spin-photonics is another emerging area where indigenously

developed GaAs photodetectors can play an important role. In

these experiments, detection of the degree of circular

polarization (DCP) of light emitted by QW samples is

correlated with the density of spin-polarized electrons [26]. A

major hurdle in such experiments is to detect a very weak

spin-polarized PL signal, typically of few nW power. In such

an experiment, strength of the signal is mainly governed by

the spin relaxation mechanisms acting in the QW sample. One

usually opts for a photomultiplier tube (PMT) for such

sensitive measurements. Figure T.4.7 shows the outcome of

such an exercise where DCP of a QW sample is measured with

the help of a PMT and also by an indigenously developed

GaAs photodetector.

DCP of PL signal of a quantum well sample

measured by using an indigenously developed GaAs

photodetector and a PMT.

It is quite encouraging to see that the indigenous device can

deliver the desired outcome even in such specialized

experiments. From the magnetic field dependence of DCP, an

electron spin relaxation time of 50 ps (± 3.5 ps) is estimated.

This also demonstrates the usefulness of indigenously

developed detectors in the measurement of spin lifetime of

charge carriers in a QW sample.

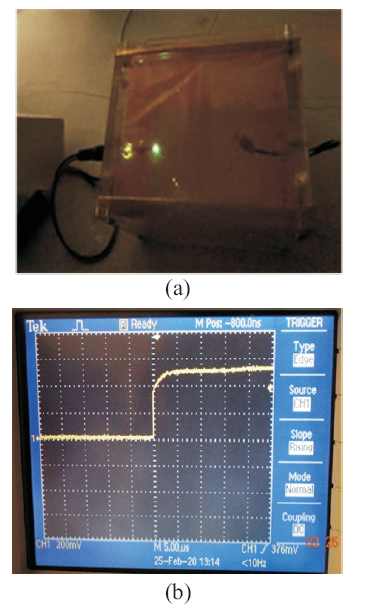

3.3 Arc fault detection system for RF circulator

Customized single element GaAs based PIN photodetectors

are made for arc fault detection applications in radio

frequency (RF) circulator systems. A quick response of the

sensor is critical for this application. Keeping this in mind, the

temporal response of indigenously developed photodetectors

is measured by using femtosecond laser pulses and is found to

be ~ 2.5 ns. Initially, the performance of GaAs photodetector

for safety operation is checked by developing a lab-based arc

ignition facility. A photograph of this facility is shown in

Figure T.4.8(a). Here, an arc is artificially generated for a predefined

duration and the response of GaAs sensors is tested

with respect to arc test pulse. One representative pulse

recorded by the GaAs sensor is shown in Figure T.4.8(b). It

can be seen that the sensor can read the arc pulse within a

period of < 5 ms, which is sufficient for meeting the user

requirements.

(a) Photograph of a test setup for arc fault

detection. (b) Trace of an arc pulse detected by the GaAs

sensor.

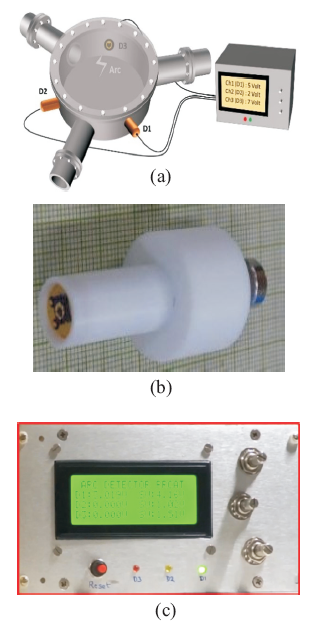

Next, an arc fault detection system is designed and developed

by using a trans-impedance amplifier and GaAs PIN

photodetectors. The system contains mainly three input

channels for the connection of sensors and an LCD display to

show the magnitude of signal corresponding to each sensor. A

schematic diagram of arc fault detection system deployed in a

RF circulator is shown in Figure T.4.9(a). Necessary mounts

for holding GaAs photodetectors are also made as shown in

Figure T.4.9(b). GaAs photodetector elements are placed at

the tip of mount which has a BNC output connector at the

other end. It is ensured that the detector assembly is

compatible with RF environment. Further, the system

contains a scaling circuit and STM-32 microcontroller for the

digitization of analog signals and to display the digitized

signal on a 20x4 LCD screen as shown in Figure T.4.9(c). This

system continuously monitors the three sensors and triggers

an alarm at a pre-settable value. Whenever an arc is detected

by any of the three sensors, it generates an audible as well as

visible alarm.

(a) Schematic diagram of arc fault detection system

with three input channels, (b) photograph of an indigenously

developed GaAs sensor for arc fault detection, and (c)

photograph of the control panel of arc fault detection system.

Further, the safety system latches the alarm state until the

same is cleared by the user. Potential free normally-closed

contacts are provided to user as additional safety measure for

shutting down the load in case an alarm is triggered. After a

series of tests in lab, indigenously developed arc fault

detection system is deployed in the RF circulator, developed

by RFSD, RRCAT which primarily works as a safety

interlock for switching off the electrical supply as per the user

requirement. The system is in regular use at RFSD in RF

circulator operating at about 40 kW power.

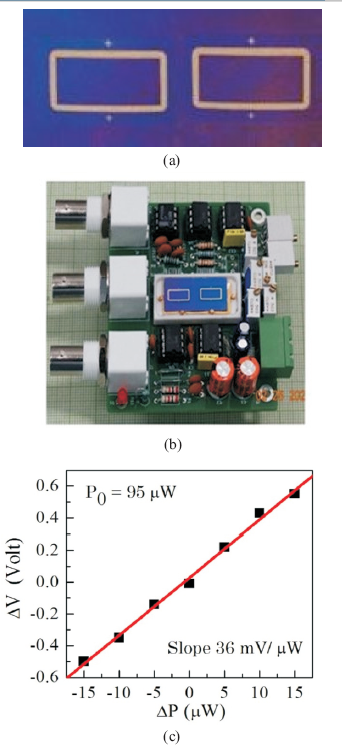

3.4 Balanced photodetector for laser spectroscopy

applications

Balanced photodetectors find several interesting applications

in laser spectroscopy. Here, one measures the difference in the

intensity of two laser beams, which are of same intensity and a

minor difference is caused by some physical phenomenon. In

order to do this, a very sensitive detection unit is required by

the user that is capable of measuring a very small difference in

the intensity of two laser beams with a high signal-to-noise

ratio. In view of this, balanced photodetectors are quite

attractive since laser noise or any other common noise can be

canceled out. This leads to the detection of a weak signal

overriding on a large DC background. In a balanced

photodetector, two photodetectors are connected in such a

way that the effective output becomes zero, as long as the

intensity of laser beams incident on the two detectors is same.

This imposes a stringent condition to make the performance

of two photodetectors almost identical. In order to achieve

this, two identical GaAs based photodetectors (PD & PD ) are 1 2

fabricated on a single chip as shown in Figure T.4.10(a). The

detectors are of 4 x 7 mm2 size along with a spacing of 3 mm

as required by the user. A rectangular geometry of detector

element is required to accommodate an elliptical laser beam

as per the user requirement. Further, a large size of detectors is

needed to minimize the error due to any minor displacement

of the laser beam during the experiments. In order to minimize

the noise, and also to keep the assembly compact, a special

packaging is designed and developed as shown in Figure

T.4.10(b). The dual detector chip is mounted on a PCB along

with all the readout electronics. The photocurrent from PD1

and PD is amplified by LF356 operational amplifier based 2

trans-impedance amplifiers which is further amplified by

variable gain voltage amplifiers. The amplified signals are

then processed through INA105 precision unity gain

differential amplifier. The dual-element detector along with

the electronics is packaged in a metal box and provision to

read the output of individual detectors along with the

differential signal is made available to the user. The

performance of the complete system is tested by using a

633 nm He-Ne laser. The incident power (P ) on PD is fixed at o

95 ìW and that of PD2 (Po+ÄP) is varied by using a circularly

variable neutral density filter. The dual-element detector is found to be extremely sensitive to the difference in incident

power with a sensitivity of 36 mV/ 1 ìW as shown in Figure

T.4.10(c). It is important to note that such specialized

balanced photodetectors are not commercially available.

(a) Photograph of dual element GaAs

photodetector chip, (b) Photograph of balanced

photodetector system, where dual element detector is

mounted on top of PCB, (c) the differential signal generated

(ÄV) as a function of difference in incident power (ÄP).

3.5 GaAs based x-ray detectors

GaAs photodetectors find interesting applications in x-ray

region of electromagnetic spectrum due to their radiation

hardness along with a high photon absorption efficiency when

compared to silicon [8-10]. In view of this, prototype x-ray

detectors based on GaAs materials are also fabricated. Such

detectors operating in the range of 20–100 keV are attractive

for medical imaging applications. Silicon detectors are not

ideal for x-ray applications in 20–100 keV range since silicon

has quite a low absorption above 20 keV. In view of this, GaAs

based PIN photodetectors with very thin p-GaAs layer are

specially grown. Photodetectors are fabricated and are

successfully tested against laboratory based CuKa x-ray

source. The energy-dependent x-ray response of GaAs PIN

detector is also measured by using a monochromatic x-ray

beam with energy varying from 8 to 25 keV at BL-2 beamline

of Indus-2 synchrotron radiation source as shown in Figure

T.4.11. It confirms the suitability of indigenously developed

GaAs detectors over a wide x-ray spectral range. Further

refinements for enhancing the signal strength and also to

widen the energy range are in progress.

Spectral response of indigenously developed

GaAs based x-ray detector recorded at BL-2 beamline of

Indus-2.

4. Radiation hardness of indigenously developed GaAs

based PIN photodetectors

GaAs is expected to be radiation hard when compared with

commercially available silicon photodetectors. In view of

this, GaAs photodetectors were exposed to 360 kGy of ãradiation

[23-25]. All the irradiations were performed at room

temperature in a 2490 Curie 60Co gamma chamber (Model No;

GC-900) supplied by the Board of Radiation and Isotope Technology, Mumbai. After the exposure of GaAs detectors to

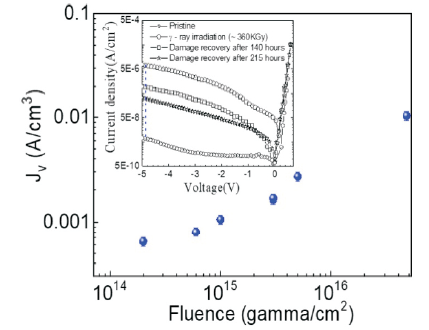

ã-rays, an increase in the dark current per unit volume (J ) is v

seen as a function of ã-ray fluence (F) as shown in Figure

T.4.12.The slope (á = DJv/DF) of the current per unit volume

versus ã-ray fluence is estimated to be ~5 x10-l9 A/cm for GaAs

which is lower by an order of magnitude when compared to Si.

A lower value of á confirms that radiation tolerance of GaAs

is more than that of Si, particularly in the high flux ã-ray

environment. Results shown in the inset of Figure T.4.12

confirm that there is a significant recovery of the radiation

damage as the time elapsed after the irradiation. Such an

improvement is predominantly due to the reduction of carriers

contributing to the saturation current. Thus, it is proven that

the radiation induced defects can be partially recovered even

without any high temperature annealing step [27-29]. Such a

self-recovery of GaAs based devices is really attractive. Due

to such attributes, GaAs based detectors are attractive for

many applications in high temperature, high radiation zones,

for example direct electron detection spectrometer, and also

for space science missions [30-32].

Reverse saturation current per unit volume as a

function of irradiated dose, inset shows the recovery of

radiation induced damage as a function of cumulated

annealing time at RT.

5. Conclusion

A complete technology for the fabrication of GaAs based

photodetectors is developed. It involves design and multilayer

growth by MOVPE technique and various devices fabrication

steps that are needed for the fabrication of GaAs detector

chips. The fabrication steps are also optimized for customized

applications. Thereafter, GaAs based photodetectors are used

in spectroscopy experiments to record the PL spectra of

various QW samples. Performance of GaAs based detectors is

found to be similar to that of commercially available silicon

photodetectors. GaAs based photodetectors are found suitable to replace the PMT in low noise applications for

measuring the DCP of PL signal emitted by a QW sample. An

arc fault detection system based on GaAs photodetectors is

also developed and is deployed in RF circulator as a safety

system to switch off the load in case an arc is detected. A

balance photodetector assembly is developed by

incorporating a custom built dual detector chip for interesting

applications in laser spectroscopy. GaAs based x-ray

prototype detectors are also made which works in the energy

range of 12 to 25 keV. It demonstrates our capabilities for the

development of customized radiation hard photodetectors

based on GaAs epitaxial layers. Development of a few more

customized semiconductor photodetectors as per the needs of

RRCAT users is in progress. Finally, the radiation tolerance of

GaAs photodetectors is measured by exposing the devices to

360 kGy of ã-radiation. The devices were found to be

operational even after exposure to such a high dose and their

radiation tolerance is found to be an order of magnitude higher

when compared with commercially available silicon photo

detectors. The technology developed here can find several

interesting applications in the harsh environment of high

temperature, high pressure, and high radiation zones.

Acknowledgement

In this article, we have summarized the work which has been

carried out by the entire team of Semiconductor Materials

Laboratory during the last few years and their contribution is

hereby acknowledged. We acknowledge the colleagues from

RFSD, LPAS, SUS, FSOSS, LCID, Laser Workshop and

Chemical Treatment Laboratory, who had made useful

contributions. In particular, Dr. Ashish Kumar Tiwari, RFSD,

Dr. S. P. Ram, LPAS, and Dr. S. K. Rai, SUS contributed in the

development of customized devices. Authors would like to

thank Shri S. V. Nakhe, Director, Materials Science Group

and Shri Debashis Das, Director, RRCAT for their constant

support and encouragement.

|