|

Responsibilities of BMEL

- Design, fabrication, testing, installation and commissioning of front-ends (FEs) for 21 bending magnet based beamlines and 5 Insertion Devices (I.D.) based beamlines.

- Up-gradation and maintenance of the installed front-ends of Indus-2.

- Design and development of import substitutes of the beamline and front-end components like ultra high vacuum (UHV) compatible Pre-Mirror and Post-mirror systems, diagnostic devices like beam viewer cum wire monitor and 4 blade monitors, water-cooled fixed mask and slits, water-cooled shutter, safety shutter, collimator, vacuum chambers, differential pumping systems and customized UHV pumping setups.

- Installation, assembly, testing and commissioning of Indus-2 beamlines. It includes layout design, supervision of fabrication and installation of radiation shielding hutches.

- Design and fabrication of experimental stations of Indus-1 and Indus-2 beamlines as per the user's requirement.

Highlights of the work carried out by BMEL

(A) Front-end

-

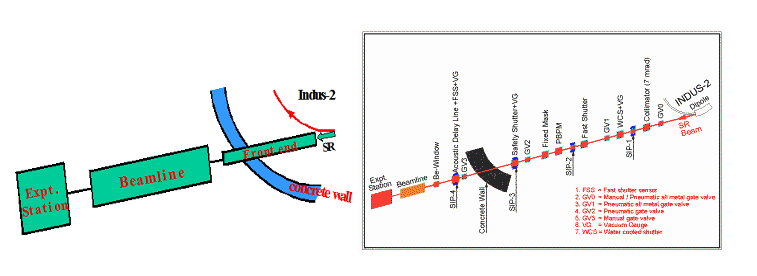

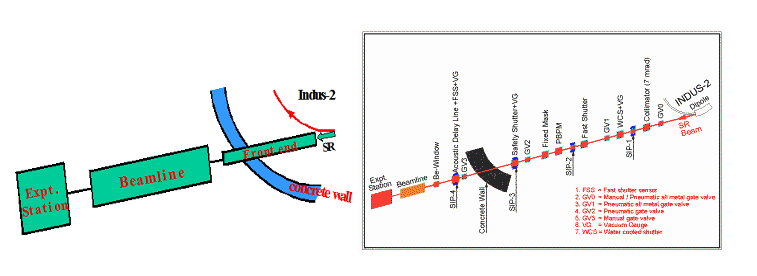

Front-end is an interface between synchrotron radiation (SR) source and a beamline.

-

Each front-end is about ~ 15 meters long ultra high vacuum assembly consisting of various components like vacuum shutters, valves, beam diagnostic devices such as beam viewer and wire monitor, water-cooled masks, long vacuum chambers with vacuum gauges and sputter-ion pumps.

-

The design of a front-end depends upon type of sources and beamlines. Indus-2 front-ends will be different for each source type like bending magnet, wiggler, wavelength shifter, undulator etc. and beamlines like hard x-rays, soft x-rays, visible and infrared.

Functions of the front-ends -

A typical front-end has to perform the following functions :

-

Storage ring vacuum protection :- Any vacuum failure in a beamline can spoil the vacuum of the storage ring. This protection is obtained by triggering protective measures against any vacuum failures that can propagate along the FE to storage ring.

- Absorption of heat load of synchrotron and ionising radiation:- Thermal load associated with SR beam from the bending magnet is ~ 30W/mrad horizontal with total heat load of 720 watt. SR beam from undulator has maximum heat load of about 3 kW. Along the beamline Bremsstrahlung radiation that originates from the scattering of the 2.5 GeV electron beam is rather high. When the beam line is not operational, this heat load and the Bremsstrahlung radiation need to be stopped.

This is done by providing a safety shutter system, which absorbs the full thermal power of the SR beam and also Bremsstrahlung.

- Beam definition :- To limit the horizontal divergence of SR beam to the required value, a beam definition system is required. This is done by using a collimator as well as fixed mask which will limit the excursion of the photon beam and thus prevent the photon beam from striking any uncooled part of FE and the beamline.

-

Beam position monitoring:- This is monitored by the photon beam position monitors like beam viewer, wire monitor, blade monitor which gives the average position of the photon beam. The feedback from beam position monitor is used to control the average take –off angle of the photon beam with the help of steering coils.

- Beryllium window:- In hard x-ray beamline, beryllium window is used to isolate the vacuum of the front-ends and storage ring from that of the beamline thus allowing to operate the beamline at lower vacuum. Beryllium window permits only the hard x ray part of SR beam to pass through it to the beamline.

Status of the Indus-2 Front-ends

-

Bending Magnet front-ends : Till June 2020, 19 bending magnet based front-ends have been installed at Indus-2 out of which 17 FEs are operational and being used to cater the synchrotron radiation (SR) beam to different beamlines. Two FEs are ready to provide SR beam to the beamlines BL-17 and BL-26 as soon as the beamlines are ready. The installed front-end is shown below.

-

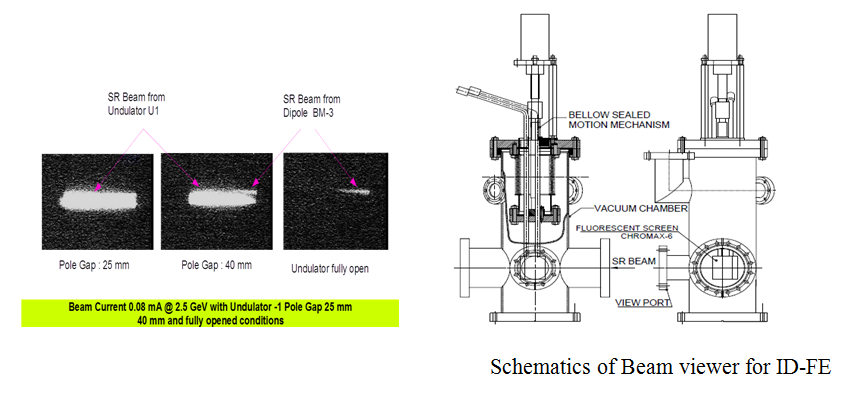

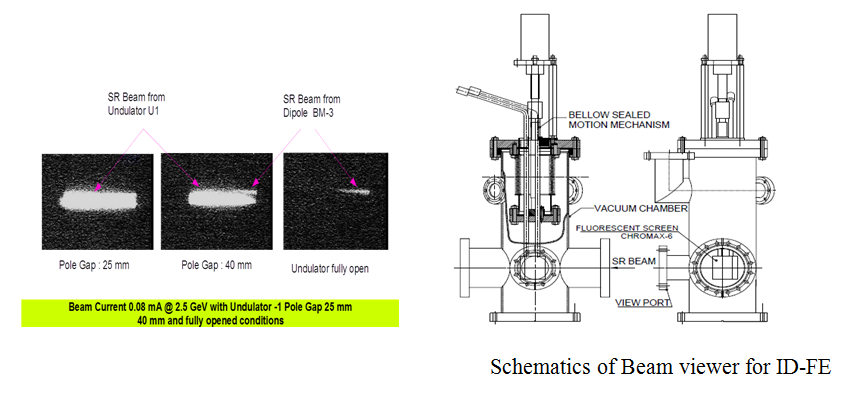

Insertion Devices (IDs) front-ends : 4 nos. of I. D. based front-ends have been installed at Indus-2 for providing the SR beam from undulators U1, U2, U3 and wavelength shifter to the beamlines BL-5, BL-10, BL-20 and BL-15 respectively. Very bright SR beam from undulators at low current is observed in the front-ends by means of water-cooled beam viewer developed in-house as shown in the figure.

Beamline wise status of various front-ends of Indus-2

|

S. No.

|

Front-ends

|

Beamline no.

|

User

|

Front-end Status

|

|

1.

|

Front-end for SAXS beamline

|

BL-1

|

UGC-DAE-CSR

|

Operational

|

|

2.

|

Front-end for Engineering application beamline

|

BL-2

|

RRCAT

|

Operational

|

|

3.

|

Front-end for Soft x-ray reflectivity beamline

|

BL-3

|

RRCAT

|

Operational

|

|

4.

|

Front-end for Imaging beamline

|

BL-4

|

BARC

|

Operational

|

|

5.

|

Front-end for AMOS beamline

|

BL-5

|

BARC

|

Operational

|

|

7.

|

Front-end for Lithography beamline

|

BL-7

|

RRCAT

|

Operational

|

|

8.

|

Front-end for dispersive EXAFS beamline

|

BL-8

|

BARC

|

Operational

|

|

9.

|

Front-end for scanning EXAFS beamline

|

BL-9

|

BARC

|

Operational

|

|

10.

|

Front-end for ARPES beamline

|

BL-10

|

RRCAT

|

Operational

|

|

11.

|

Front-end for EDXRD beamline

|

BL-11

|

BARC

|

Operational

|

|

12.

|

Front-end for ADXRD beamline

|

BL-12

|

RRCAT

|

Operational

|

|

13.

|

Front-end for GIXS beamline

|

BL-13

|

SINP

|

Operational

|

|

14.

|

Front-end for XPES beamline

|

BL-14

|

BARC

|

Operational

|

|

15.

|

Front-end for ECXRD beamline

|

BL-15

|

BARC

|

Installed

|

|

16.

|

Front-end for XRF beamline

|

BL-16

|

RRCAT

|

Operational

|

|

17.

|

Front-end for Radiological Safety beamline

|

BL-17

|

BARC

|

Installed

|

|

18.

|

Front-end for SWAXS beamline

|

BL-18

|

BARC

|

Operational

|

|

20.

|

Front-end for XMCD beamline

|

BL-20

|

RRCAT

|

Operational

|

|

21.

|

Front-end for Protein Crystallography beamline

|

BL-21

|

BARC

|

Operational

|

|

22.

|

Front-end for PEEM beamline

|

BL-22

|

BARC

|

Operational

|

|

23.

|

Front-end for Beam Diagnostic (X-Ray) beamline

|

BL-23

|

RRCAT

|

Operational

|

|

24.

|

Front-end for Beam Diagnostic (Visible) beamline

|

BL-24

|

RRCAT

|

Operational

|

|

26.

|

Front-end for intermediate energy range x-ray absorption beamline

|

BL-26

|

UGC-DAE-CSR

|

Installed

|

Major Front-end components developed in-house

- Collimator - First FE component to interact with SR beam. It consists of water-cooled copper block having fixed aperture to restrict the incoming 24 mrad SR beam to 7 mrad downstream side. It can absorb 600 watt heat load safely.

- Water-cooled shutter - A water-cooled copper block is moved up and down inside a vacuum chamber to intercept the incoming SR beam completely. The shutters are designed to absorb heat load up to 600 watt for SR beam from bending magnet and 2500 watt from undulators. They are operated remotely by means of pneumatic actuator.

- Diagnostic devices - 3 types of devices like wire monitor, beam viewer and 4 blade monitor are developed to observe the position, shape and profile of the SR beam. Beam viewer shows the SR beam on a fluorescent screen of chromium doped alumina (CHROMOX-6) baked by water-cooled copper plate inside a vacuum chamber. Wire monitor uses a scanning wire to see the position and profile of beam.

- Safety shutter - It is a water-cooled vacuum shutter which moves a densimate (Tungston alloy) block inside a vacuum chamber to absorb the bremsstrahlung along with SR beam. Safety shutters for undulator front-end can also absorb heat load up to 2000 watts.

- Water-cooled masks for ID front-ends - These masks are designed to provide defined size of the SR beam thus absorbing unwanted radiation and heat load up to 2000 watt as.

(B) Beamlines

BMEL has been involved in the upgradation and maintenance of the following beamlines of Indus-2 for round the clock operation.

- Engineering application beamline BL-2

- Soft x-ray reflectivity beamline BL-3

- Lithography beamline BL-7

- ARPES beamline BL-10

- ADXRD beamline BL-12

- XRF beamline BL-16

- XMCD beamline BL-20

Major Beamline components developed in-house

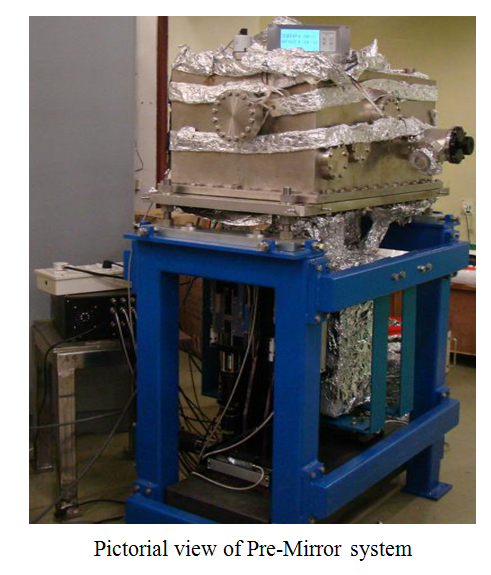

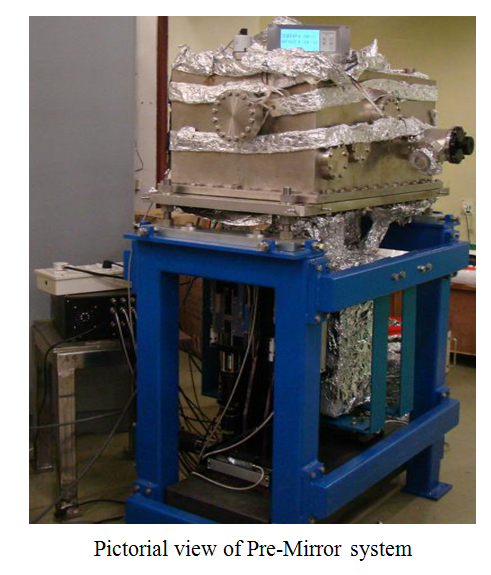

Pre and post Mirror system:

Pre mirror system is used for focusing the white SR beam while the post mirror system is used for focusing the monochromatic SR beam. The pre-mirror system consists of an UHV chamber of required size and configuration, chamber support structure with alignment system and mirror manipulation mechanism to manipulate the mirror precisely with 1μm resolution under UHV condition in required degrees of freedom. The mirror is remotely operated with safety interlock and position sensing.

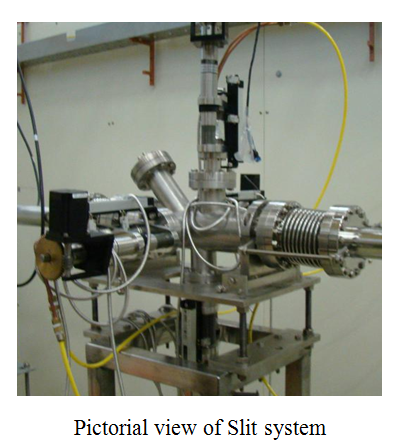

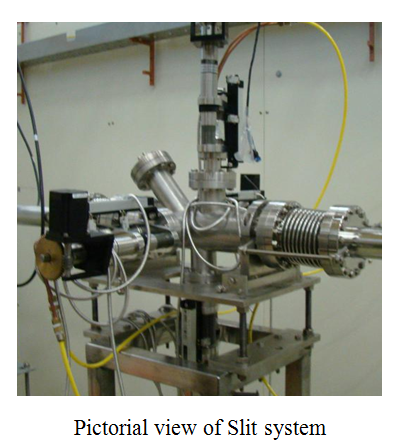

Water cooled slit system:

UHV compatible water cooled slit system is developed to precisely define the white beam size in the XRF Microprobe beamline. Slit system is 4 blade type. Each blade is independently actuated and water cooled separately. The linear motion is provided through a UHV compatible welded bellow sealed linear motion system. The total range of linear motion is 50 mm. The cooling of slit blade is done through a water-cooled Cu plate without any water to vacuum joint.

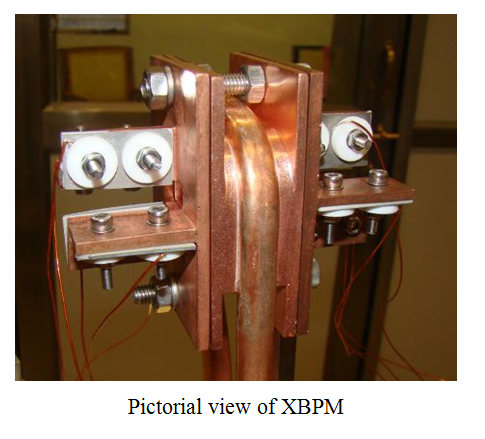

Beam position monitor (BPM):

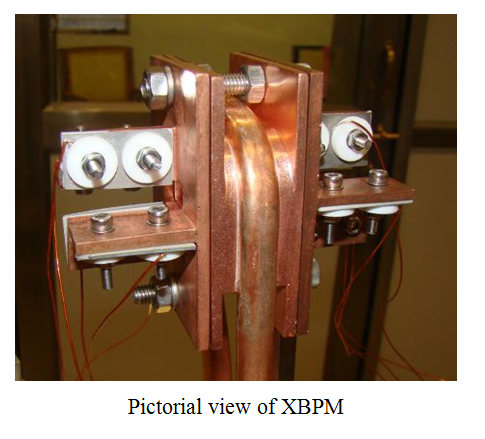

Scanning wire monitors and water-cooled beam viewers developed in house are being used to monitor the SR beam in the beamlines. In addition a 4 blade x-ray beam position monitor (XBPM) is also developed and installed in a beamline for monitoring the SR beam position. The Tungsten blades are housed in a UHV chamber and cooled through a water-cooled Cu plate. The blades in each direction are arranged in pair of 2 blades such that incident SR beam will fall on the bottom curved edge of each blade. Each blade partially cuts the unused portion of the SR beam so that it can remain continuously in line of the SR beam. The blade assembly can be actuated orthogonal to SR beam direction. The total range of linear motion is 40 mm in vertical direction and 15 mm in horizontal direction (orthogonal to beam direction) with a motion resolution of 1 micron.

Publications:

- Modi M.H., Gupta R.K., Kane S.R., Prasad V., Kant C., Yadav P.K., Raghuwanshi V.K., Singh Amol, Sinha M.

A soft x-ray reflectivity beamline for 100-1500 eV energy range at Indus-2 synchrotron radiation source

AIP Conf. Proc, Vol. 2054, p. 060022, Jan. 2019.

https://doi.org/10.1063/1.5084653

- V. K. Raghuwanshi, P. K. Gauttam, Sohan Lal, Vikas Jain, Sourabh Kherde

Development of Synchrotron Beam Shutter for Undulator Front-Ends of Indus-2

Proceeding of Indian Particle Accelerator Conference (InPAC-2018}, RRCAT, Indore, January 9-12, 2018

- S. R. Garg, Kiran Baraik, Sohan Lal, Vijendra Prasad, Tapas Ganguli

Design and Development of pre-mirror system for planar undulator based ARPES beamline of Indus-2

Proceeding of Indian ParticleAccelerator Conference (InPAC-2018}, RRCAT, Indore, January 9-12, 2018

- V. K. Raghuvanshi, Vijendra Prasad, S. R. Garg, Vikas Jain

Design, Development, Installation and Commissioning of water-cooled pre-masks for undulator front ends of Indus-2,

Proceeding of Indian Particle Accelerator Conference (InPAC-2015), TIFR Mumbai, December 21-24, 2015

- V. K. Raghuvanshi, Y.Tyagi, S. Yadav, T. A. Puntambekar, Vikas Jain, Vijendra Prasad

Design, fabrication, installation and commissioning of water-cooled beam viewer for undulator front-ends of Indus-2,

Proceedings of Indian Particle Accelerator Conference (InPAC-2015), TIFR, Mumbai, December 21-24, 2015

- Chanderkant, Sohanlal, Vijendra Prasad, V. K. Raghuvanshi

Measurement of position and profile of undulator radiation in Indus-2 using scanning wire monitor

Proceedings of Indian Particle Accelerator Conference (InPAC-2015), TIFR, Mumbai, December 21-24, 2015

- S. R. Garg, Vijendra Prasad, Dr. A. K. Sinha

Design and Development of mirror system for ADXRD beamline of Indus-2

Proceedings of Indian Particle Accelerator Conference (InPAC-2015), TIFR, Mumbai, December 21-24, 2015

- M. K. Tiwari, P. Gupta, A.K. Sinha, S.R. Kane, A.K. Singh, S.R.Garg, C.K. Garg, G.S.Lodha and S.K.Deb

A microfocus X-ray fluorescence beamline at Indus-2 synchrotron radiation facility

Journal of Synchrotron Radiation (2013). 20, pp. 386-389

- Sohan Lal, C. P. Paul, C. H. Premsingh, P. Bhargava, S. K. Mishra, V. K. Raghuvanshi, L. M. Kukreja, S. K. Deb

Parametric Dependence and Characterization of Laser Brazed Copper-Stainless steel joints

International conference on advances in materials and processing challenges and opportunities

AMPCO – 2012, IIT, Roorkee, India, November 02-04, 2012

- Rajvir Singh, KK Pant, Shankar Lal, DP Yadav, SR Garg, V. K. Raghuvanshi, G Mundra

Vacuum brazing of Accelerator components

International Symposium on Vacuum Science & Technology and its Application for Accelerators, Journal of Physics: Conference series 390 (2012) 012025

- Tiwari M.K., Sinha A.K., Gupta P., Singh A.K., Kane S.R., Garg S.R., Garg C.K., Lodha G.S., Deb S.K.

A microprobe-XRF beamline on Indus-2 Synchrotron Radiation Source

11th International conference on Synchrotron Radiation Instrumentation, Lyon, France, July 9-13, 2012.

Team Members of BMEL

- V. K. Raghuvanshi

-

Scientific Officer‘H’, Head, BMEL

- S. R. Garg

-

Scientific Officer‘G’

- Sohan Lal

-

Scientific Officer‘E’

- P. K. Gauttam

-

Scientific Officer‘D’

- Mohit Kumar Srivastava

-

Scientific Assistant ‘E’

- Jitendra Singh

-

Scientific Assistant ‘C’

- Suraj Das

-

Tech. Sup./A(Drg.)

- Arjun Kumar

-

Sr.Techn/H

- B. K. Gayakwad

-

Foreman/A

- Khakse Nilesh Devidas

-

Techn/F

- Rupesh Soni

-

Techn/B

|