Home Page Superconducting Cavities Development Division

Home Page Superconducting Cavities Development Division

Superconducting RF Cavity Development

The superconducting cavity made of Niobium is the basis of any high energy linear accelerator. The proposed superconducting proton linac for the Indian Spallation Neutron Source Project would require a large number of multi-cell superconducting cavities.

The developmental activities related to SCRF cavities are summarized as below:

- 1.3 GHz Tesla type elliptical cavities

- 650 MHz (Beta=0.9 and 0.92) elliptical cavities

- Cavity tuner development

- SRF Cavity Dressing Infrastructure

The superconducting cavities are being developed under (IIFC) mutual collaboration between RRCAT (Indian Institute) and Fermilab (USA). These cavities are extremely sensitive to geometric changes due to high accelerating gradient (Eacc) and high quality factor (Q). It requires high level of quality control at every stage of fabrication and processing.

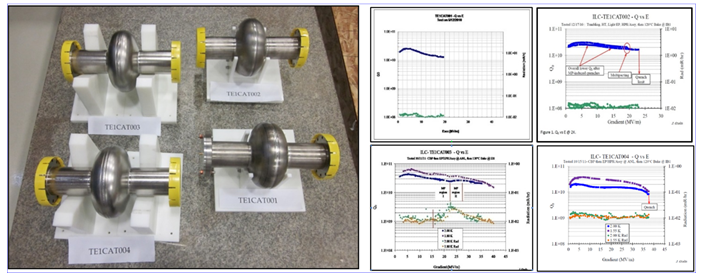

RRCAT started work on superconducting cavity manufacturing technology with 1.3 GHz (ILC type) cavities. Initially two prototype single cell superconducting cavities were developed. Subsequently, two more single cell cavities were developed with improved fabrication process. These were processed and tested at 2K in collaboration with Fermilab.

1.3 GHz single cell cavities and their result at 2K

After the initial successful development of 1.3 GHz single-cell superconducting cavities, the development of 1.3 GHz five-cell superconducting cavities has been initiated as a next step. The development of a multi-cell superconducting cavity has additional challenges associated with their RF measurement and electric field flatness measurement and its control. This 1.3 GHz five cell cavity was successfully tested at Fermilab, USA. Acceleration gradients of 20.3 MV/m at 2K and 42 MV/m at 1.5-1.7K were achieved with a high quality factor of 2 x 1010 in this cavity.

|

|

|

|

5-cell 1.3 GHz cavity on VTS insert

|

Q0 v/s Eacc plot of cavity cold test

|

The development of a 1.3 GHz nine-cell superconducting cavity was done as the next step. The cavity was processed and tuned using facilities developed at RRCAT.

|

|

|

Nine-cell 1.3 GHz SCRF cavity

|

single-cell 650 MHz (Beta=0.92) superconducting cavity has been fabricated using the in-house electron beam welding facility. The cavity was successfully processed and tested at 2 K in VTS facility. This cavity achieved accelerating gradient (Eacc) of 19.3 MV/m with quality factor Q0 of 7x1010 at 2K.

|

|

|

|

|

650 MHz single-cell Nb cavity

|

Cavity mounted on VTS with FTS

|

Eacc vs Q0

|

Based on the experience gained during earlier work on 1.3 GHz multi-cell SCRF cavity development, a detail manufacturing process sequence plan was made for 650 MHz five-cell SCRF cavity. Various machining and welding fixtures were also designed and fabricated. The cavity is welded using in-house 15 kW EBW machine facility.

|

|

|

Fabricated first 650 MHz 5-cell cavity

|

The VTS test was carried out on first cavity and low field quality factor 4 x 1010 and an accelerating gradient of 17.5 MV/m was achieved.

|

|

|

|

First 650 MHz 5-cell cavity test result at 2K

|

Fabrication of six more five-cell 650 MHz (Beta=0.92) superconducting RF (SCRF) cavities have been completed using the in-house infrastructure. Machining of components was carried out at Indian Industries which were developed previously to make them ready for future large scale requirements. Presently, these cavities are in various stages of processing and testing.

|

|

|

Fabricated cavities ready for further processing and testing

|

Tuner Development for SCRF Cavities:

The tuner is an essential part of the SCRF cavity, which not only corrects the resonant frequency of the RF cavity for manufacturing errors, but also controls the cavity RF resonance frequency during accelerator operation. Various types of tuner related activities for design, prototype manufacturing and testing have been taken up at RRCAT. The X-Link tuner as well as the lever tuner have been developed in RRCAT as shown in the figure below. X-Link Tuner is RRCAT's innovative design which has the capability to operate in either compression mode or expansion mode. The lever tuner is a FermiLab’s design, which has also been manufactured in RRCAT under IIFC collaboration.

Development and testing of an X-Link tuner for a superconducting RF cavity

The X-Link tuning mechanism is being developed based on the RRCAT design, which has received four patents from Japan, Europe, the US and India. This tuner is capable of performing slow and fast tuning operations as per the requirement of SCRF cavities.

|

|

|

|

X-link tuner with single-cell SCRF cavity

|

Phase response of cavity at piezo excitation of 62V, 10ms pulse, 4Hz repetition rate

|

The X-Link tuner has been tested with a 650 MHz single-cell SCRF cavity as shown in the figure for slow and fast tuning for range and resolution according to design parameters. Control systems have also been designed and developed for both slow and fast tuning systems. Tuner control was performed by running the motor and piezo at room temperature as well as cryogenic temperature. The piezo was operated at 100V with a half sinusoidal pulse width of up to 1 ms and a repetition rate of 50 Hz. The pulse width, repetition rate and amplitude of the piezo excitation varied in each trial in order to study the system for rapid tuning. The phase response of the cavity for piezo excitation of 10 ms pulse width at 62V and repetition rate of 4Hz is plotted in figure below. In addition this tuner will be tested in Horizontal Test Stand (HTS) at 2K temperature with high beta 650 MHz 5-cell SCRF cavity.

Lever Tuner:

The mechanism has a double lever arrangement with a mechanical advantage ratio of approximately 20:1. Two piezo actuators are mounted in the center between the cavity transition ring and the tuner lever to transmit force directly into the cavity. For stepper motor (slow actuator) operation and piezo (fast actuator) operation of the tuner, tuner was characterized for its properties at room temperature with a high beta 650 MHz dressed cavity as shown in figure. In addition, this tuner was tested for slow tuning range and resolution in the superconducting state of the cavity at 2K in HTS.

|