|

Design & Manufacturing Technology Division |

Design & Manufacturing Technology Division

Design & Manufacturing Technology Division

Technology & Product Development Section

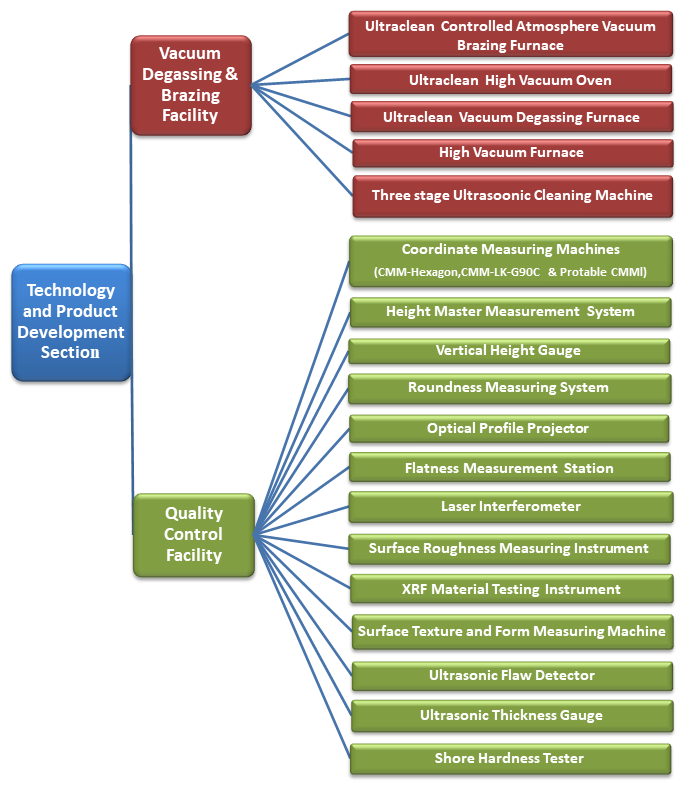

Technology and Product Development Section (TPDS) is a tiny team of highly committed technocrats that plays a very unique role in the division. It takes up leadership role of anticipating future requirements of joining technologies, develops the technology and presents a choice to the design engineers to use the technology. It has developed various new technologies in fusion welding, furnace brazing and diffusion bonding to serve the projects. It has expertise in dissimilar material joining. It also helps projects by developing new products by bridging the gap areas.

In addition, this section also provides quality control services to the division in precision metrology, flaw detection and material identification. It has vacuum heat treatment, degassing and brazing furnaces withdry vacuum pumping systems to cater to demands of unconventional technologies during manufacturing of highly demanding precision components of particle accelerators.

Team Members-

Shri Abhay Kumar, SO/H, Head, Technology & Product Development Section.

The team consists of 15 members including Engineers and skilled technicians along with skilled designing team following facilities are available in the section.

- Vacuum Degassing & Brazing Facility

TPDS has various ultra clean vacuum furnaces along with ultrasonic cleaning facility.

1.1) Ultraclean Controlled Atmosphere Vacuum Brazing Furnace

1.2) Ultraclean High Vacuum Oven

1.3) Ultraclean Vacuum Degassing Furnace

1.4) High Vacuum Furnace

1.5) Three Stage Ultrasonic Cleaning Machine

- Quality Control Facility

For Quality control and inspection, this facility is equipped with high precision measuring machines and equipment.

2.1) 3-Axes coordinate measuring machine (CMM-Hexagon)

2.2) 3-Axes coordinate measuring machine (CMM-G-90C)

2.3) 7-Axes Portable Coordinate Measuring Machine (Portable-CMM)

2.4) Height Master Measurement System

2.5) Vertical Height Gauge

2.6) Roundness Measuring System

2.7) Optical Profile Projector

2.8) Flatness Measurement Station

2.9) Laser Interferometer

2.10) Surface Roughness Measuring Instrument

2.11) XRF Material Testing Instrument

2.12) Surface Texture & Form Measuring Machine

2.13) Ultrasonic Flaw Detector

2.14) Ultrasonic Thickness Gauge

2.15) Shore Hardness Tester

|

|

Design & Manufacturing Technology Division

Design & Manufacturing Technology Division