| Ultra High Vacuum Technology Section |

Technology Development

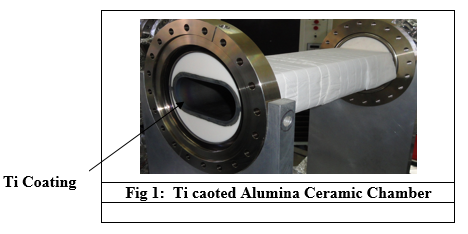

- Development of Titanium Coating process for Alumina Ceramic Chamber

Alumina ceramic UHV chambers is used for fast pulsed pinger magnets in Indus-2 to mitigate the eddy current issue. Internal surface of this chamber requires Titanium coating to provide conducting path to image current. Technology of UHV compatible uniform thickness (0.5 micron±10%) coating of Titanium for alumina ceramic chamber (86mm x 36mm) aperture was developed in UHV Lab using the DC Magnetron Horizontal Sputter Coating system. Process parameters, for Ti coating, were optimized by successive trials on glass and ceramic samples. Repeatability of coating was also confirmed with optimized process parameters. Adhesion of coating was also checked by tape test as per ASTM-D3359. No peel off was observed after coated sample was subjected to multiple (05 times) thermal cycling (room temperature to 150°C to room temperature). Optimized process parameters are shown in Table-1.

Measured thickness of titanium coating in coated ceramic tube was found to be ~0.55 micron. Post coating, an ultimate vacuum of ~8.0x10-10 mbar was achieved. Coated ceramic tube was further subjected to characterization with pinger magnet. Photograph of ceramic chamber coated with Ti is shown in Figure-1. One such chamber has been successfully installed with vertical pinger magnet in Indus-2 and working satisfactorily.

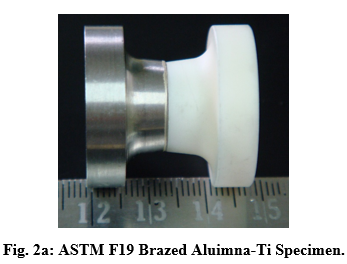

- Development of Alumina to Titanium Brazed Joint

To overcome the issue of eddy current effects, alumina ceramic chambers are required for pulsed kicker magnets of accumulator ring of IFSR. Titanium as end flange for UHV sealing of alumina ceramic chamber is preferred due to: its compatibility with respect to co-efficient of thermal expansion of alumina, non-magnetic nature and extremely short radioactive half-life. Technological breakthrough has been accomplished by successful vacuum brazing and testing of UHV compatible un-metalized alumina (99.7% pure) to titanium-Gr-5 joints. Brazed specimen as per standard ASTM F19 is shown in Figure 3a. Brazed joints showed helium leak rate better than 2 x 10-10 mbar l/s even after 6 nos. of baking cycles at 150 °C for 8 hour soaking time. Brazing parameters were: brazing alloy- BVAg-8, vacuum ~ 4 X 10-04 mbar, temperature: 830 °C, soaking time: 3 minutes.

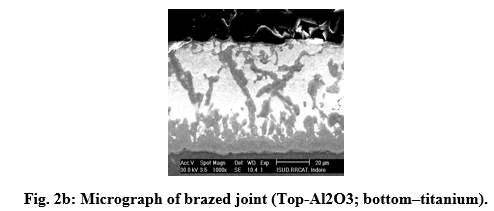

Microscopic examination of alumina/titanium braze joints revealed sound interface between the two dissimilar parts as shown in Figure 3b. The brazed joint exhibited a two-phase microstructure comprising of an Ag-rich light phase and Cu-Ti-V grey phase. Formation of a thin continuous Ti-Cu-Al-V film on the alumina surface appears to be responsible for satisfactory wetting of alumina by the brazing alloy. Mechanical characterization of brazed joints was also carried out. 4-point bend test of brazed sample as per ASTM C1161 showed bending strength > 50 MPa, an international benchmark of bend strength of ceramic to metal joint.

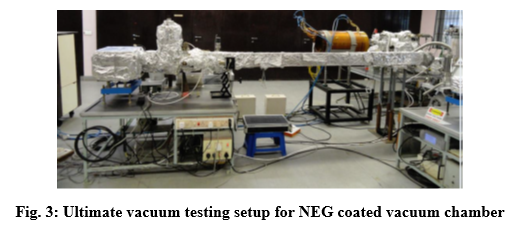

- Development of NEG coating process for UHV chamber for undulators in Indus-2

2700 mm long aluminium alloy 6063-T6 vacuum chamber of internal cross-section 81mmx17mm (racetrack shape) coated with non-evaporable getter (NEG) coating of thickness ~1 micron is used for U1 & U2 undulators in Indus-2 to provide UHV condition for stored electron beam for long beam lifetime requirement. Recently one spare undulator chamber was developed indigenously and successfully coated with Ti-Zr-V ternary alloy using large DC magnetron sputtering system in-house. Process parameters, for NEG coating, were optimized by successive trials on glass and Aluminium samples. Repeatability of coating was also confirmed with optimized process parameters. Adhesion of coating was also checked as per ASTM-D3359. No peel off was observed after coated sample was subjected to multiple thermal cycling from room temperature to 150°C and back to room temperature. Extrusion chamber was finally coated with optimized process parameters and end-to-end thickness uniformity was achieved within +/- 20%. Finally the coated chamber was tested for its ultimate vacuum performance in the ultimate vacuum testing setup shown in figure-3. 8.8 x 10-12 mbar of ultimate vacuum pressure at extreme end of the NEG coated chamber was achieved after bakeout and activation. Successful demonstration of this NEG coating technology is very vital technological accomplishment towards make in India spirit and significant import substitute for future high brilliance synchrotron radiation source.

|

|